Finally got around to making a pop tester. Harbor Freight jack for $8.97. Everyone want's pix,so here they are.

Pumped it up to 3000# and nothing exploded so far.

The 1st injector tested(an old one) popped @ 1800#, let it set for 15 minutes and it held 1600# during that time. There is a plastic band on it saying--Remanfactured 3/97. Was made in Italy in 1/93.

The 2nd pix, jack disassembled.

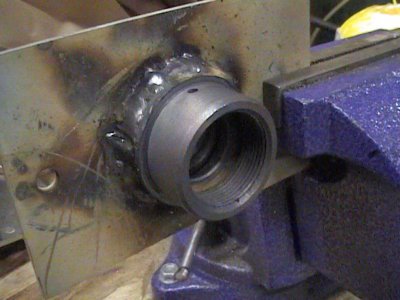

The 3rd pix, assembled the barrel to weld the cap to the plate so as not to get weld on the sealing surface.

The 4th pix, clamped for welding.

The 5th pix, cap welded with Nickel rod, cap is cast iron. Cut the excess off and doubled the thickness of the plate.

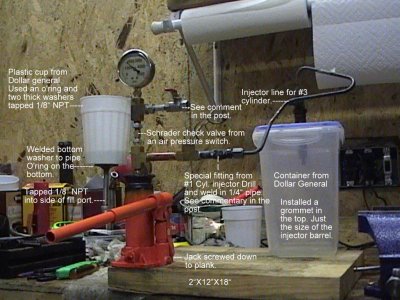

The 6th pix, all assembled with explanations.

The 7th pix, proof of injector PSI holding pressure. It popped @1800#

The valve is to relieve the pressure before disconnecting, it will dump into the tee below soon as I get the proper fittings.

That special fitting from #1 cyl, evidently is put on at the factory to time the engine. Tore it apart and it appears there is a quartz button on each side of it with a wire soldered on each side to a brass band around it. Every engine I've seen has had one of these on it. Makes a nice connection for tube on the tester.

Still have to mount another cup to supply fuel to the injector so I can see the spray pattern.

In order to get the jack to pump, had to remove the extension screw and drill a hole in the bottom of the shaft and cut a groove in the ***. Just used diesel for the fluid in the jack.

Last two pix after completion. Works great.

Mod to jack piston which I neglected to write.

Remove the adjustable bolt from the piston, comes out hard last few threads. Drill a 3/16" hole in the bottom of the piston. Hacksaw an X in the little *** at the bottom so oil can flow up thru the drilled hole. Then replace back in the cylinder. That will block off the relief hole at the top of the cyl.

Pumped it up to 3000# and nothing exploded so far.

The 1st injector tested(an old one) popped @ 1800#, let it set for 15 minutes and it held 1600# during that time. There is a plastic band on it saying--Remanfactured 3/97. Was made in Italy in 1/93.

The 2nd pix, jack disassembled.

The 3rd pix, assembled the barrel to weld the cap to the plate so as not to get weld on the sealing surface.

The 4th pix, clamped for welding.

The 5th pix, cap welded with Nickel rod, cap is cast iron. Cut the excess off and doubled the thickness of the plate.

The 6th pix, all assembled with explanations.

The 7th pix, proof of injector PSI holding pressure. It popped @1800#

The valve is to relieve the pressure before disconnecting, it will dump into the tee below soon as I get the proper fittings.

That special fitting from #1 cyl, evidently is put on at the factory to time the engine. Tore it apart and it appears there is a quartz button on each side of it with a wire soldered on each side to a brass band around it. Every engine I've seen has had one of these on it. Makes a nice connection for tube on the tester.

Still have to mount another cup to supply fuel to the injector so I can see the spray pattern.

In order to get the jack to pump, had to remove the extension screw and drill a hole in the bottom of the shaft and cut a groove in the ***. Just used diesel for the fluid in the jack.

Last two pix after completion. Works great.

Mod to jack piston which I neglected to write.

Remove the adjustable bolt from the piston, comes out hard last few threads. Drill a 3/16" hole in the bottom of the piston. Hacksaw an X in the little *** at the bottom so oil can flow up thru the drilled hole. Then replace back in the cylinder. That will block off the relief hole at the top of the cyl.

Attachments

-

DVC01385.JPG297.6 KB · Views: 382

DVC01385.JPG297.6 KB · Views: 382 -

DVC01387.JPG291.6 KB · Views: 489

DVC01387.JPG291.6 KB · Views: 489 -

DVC01392.JPG291.3 KB · Views: 483

DVC01392.JPG291.3 KB · Views: 483 -

DVC01393.JPG291.9 KB · Views: 453

DVC01393.JPG291.9 KB · Views: 453 -

DVC01395.JPG290.1 KB · Views: 470

DVC01395.JPG290.1 KB · Views: 470 -

Injector-Pop_Tester.jpg323 KB · Views: 731

Injector-Pop_Tester.jpg323 KB · Views: 731 -

DVC01399.JPG293.2 KB · Views: 361

DVC01399.JPG293.2 KB · Views: 361 -

DVC01417.JPG284.5 KB · Views: 517

DVC01417.JPG284.5 KB · Views: 517 -

DVC01418.JPG287.4 KB · Views: 445

DVC01418.JPG287.4 KB · Views: 445

Last edited: