jhenegh

Truck Still Earns its Keep

I've evidently boogered a rear main install twice now, both failing in similar fashions. They both stay dry for about a month of regular driving and then progress to serious drips. Yes I used thread sealer on the bolts to the flexplate.

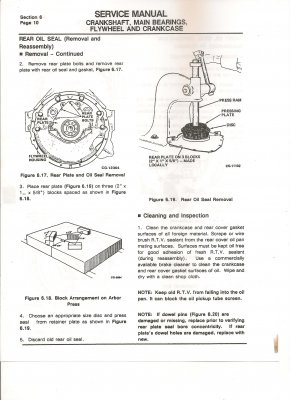

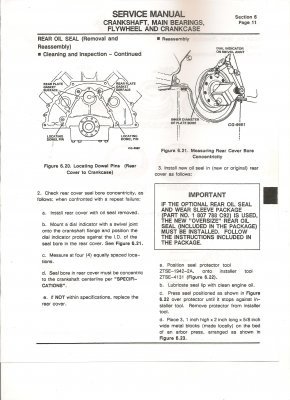

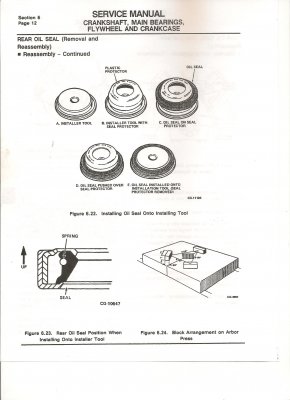

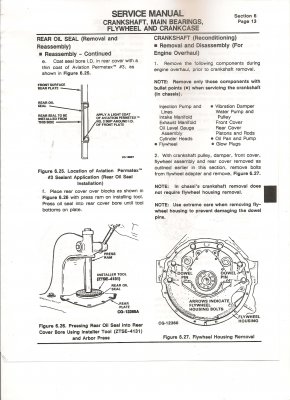

I'm thinking I have the seal plate slightly off center of the crank, so it just eventually eats up the seal. My first one was a SKF (?) seal with no sleeve, 2nd one now is the Ford part with the sleeve on the crank. Both quality I believe, so I think the problem is me or how I've got the seal plate bolted on the back of the engine.

FROM THE BEGINNING IN IN TERMS CLEAR ENOUGH I CAN DO THIS FOR A 3RD AND FINAL TIME, can someone instruct me on how to do this?? Please Because I am openly admitting two successive failures on a pretty simple job.

Because I am openly admitting two successive failures on a pretty simple job.

Thanks!

I'm thinking I have the seal plate slightly off center of the crank, so it just eventually eats up the seal. My first one was a SKF (?) seal with no sleeve, 2nd one now is the Ford part with the sleeve on the crank. Both quality I believe, so I think the problem is me or how I've got the seal plate bolted on the back of the engine.

FROM THE BEGINNING IN IN TERMS CLEAR ENOUGH I CAN DO THIS FOR A 3RD AND FINAL TIME, can someone instruct me on how to do this?? Please

Because I am openly admitting two successive failures on a pretty simple job.

Because I am openly admitting two successive failures on a pretty simple job.Thanks!