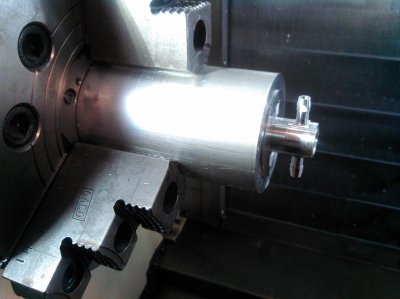

I was taken off of the machine I was making the caps on a few months ago. I bounced around from machine to machine for a while. But recently I was trained on a intergrex a lathe/mill this thing is cool!! Made a few caps tonight. How do they look? Is this design OK or is it better to have the ports offset to one side?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aluminum injector caps

- Thread starter ADV

- Start date

79jasper

Chickenhawk

Those look real good. I don't think there's really any special reason for them being offset.

Wyreth

Certifiable Noob

Offset was simply to allow higher flow to accommodate the IP return flow for the later model 7.3 return layout. Any of the IDI's can use the the early style layout, but the later model layout has much higher flow requirements on the drivers side return caps as there isn't a dedicated IP return line.

lilredtdi

Registered User

MMMMMmmmmmmm....................Candy! What's not to like with machined, billet aluminum.

Is the tubing connections press fit into the caps?

Nice work.

Is the tubing connections press fit into the caps?

Nice work.

I did not know they were offset for higher flow. One of the caps.I had at work to copy was a factory original gray cap the hole in the port was about .20 diameter but right where it met the body of the cap it was about .08 this was on a dead end cap. The ones I made have a .21 hole through the port will this be enough flow or should I reprogram to be offset? I made them this was on thinking it would be easier to copy my program and edit it to make 90 degree dead end and 3 way caps. If anything I can turn this program into caps for the 6.9

the hole size is good, and there is enough room around the injector body for the fuel flow.

I dont feel the offset would make that much difference on those nice aluminum caps.

What alloy?

I dont feel the offset would make that much difference on those nice aluminum caps.

What alloy?

The cap is machined completely out of one solid chunk of aluminum.

MMMMMmmmmmmm....................Candy! What's not to like with machined, billet aluminum.

Is the tubing connections press fit into the caps?

Nice work.

lilredtdi

Registered User

How ****! That does not even seem possible to someone who is not a machinist.

Functional bling................ How long does it take to actually make one from cutting the blank to finished product?

Functional bling................ How long does it take to actually make one from cutting the blank to finished product?

It takes about 15 minutes to make one cap after I get it up and running. The first part takes half hour or so to get the tools in the machine cutting size.

How long does it take to actually make one from cutting the blank to finished product?

thats what I figured.6061 aluminum

Nice. I have some other ideas for you to make.

icanfixall

Official GMM hand model

Good grade aluminum. It welds easy too.

Similar threads

- Replies

- 16

- Views

- 2K

- Replies

- 5

- Views

- 899

Latest posts

-

-

-

-

-

“Need help using my DTI 3300s timing meter on my 6.9 IDI.”

- Latest: WrenchWhore

Forum statistics

Members online

Total: 848 (members: 9, guests: 839)