You are probably ion the right path. At altitude you need to lean out your injected fuel amount and advance your timing to get the burn started a little sooner to compensate for the lack of air. You ought to turn the fuel down and then for a quick test, run a jump wire to your cold idle advance ( the terminal next to the fuel shutoff ) and give it a try to see if teh extra advance / less fuel combination does the trick. On most european diesels without turbos and some with that have bosch injection they have a system that compensates once above around 3400 ft by automatically reducing fuel and advancing timing and I have books on a lot of european diesel engines that have figures for manually cutting back fuel and advancing timing and it's usually done for each 3300 ft ( so if planning on operating at 6600 ft, you cut the fuel back some more and advance a tad more, if above 9900 ft , even further. If I could ever rememnber what the heck I did with the figures for transposing the bosch timing measurements to degrees of crankshaft rotation that we used to calculate the ULSD fuel timing, I could easily transpose those same type figures for altitude setting, in the mean time it'***** and missNo I mean unburned fuel dripping off the inside of the exhaust pipes when I dismantled them to check for what kinda soot was collecting in there. The pipes were wet with unburned fuel.

I'm at altitude, normal settings are not likely to work out to well here.

Something else I'm kinda curious about, I've got three wires going to the IP, One is the choke but what the other two.

I'm turning down the fuel tomorrow and if that doesn't work I can always turn it back up later.

and that's one funny video, I liked that last were the truck disappears into the cloud, OK so that's not excessive smoke but I've still got no power and unburned fuel.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuning, Turning, Tweeking the IDI 7.3

- Thread starter Boston

- Start date

What are those hoses you have running into the exhaust? To my estimation there is no way in hell that IP is going to pump enough fuel to flow wet in the exhaust, unless you would have 2-3 injectors stuck open, even then you would be blowing black smoke like you wouldn't believe and possibly filling the crankcase with fuel. I drove 780 miles like that, from SC to OH thru Virginia and West Virginia, lots of mountains pulling a 25' GN with a F350 on it. Gained a gallon of diesel fuel in the crankcase. Was actually running on only 5 cylinders, 3 - 6 - 8 injectors were stuck open. Pic below is what I pulled. The black truck is the 90 in my sig.

All that said don't solve your problem. But your just going in circles and not achieving nothing. You'll never get it right unless you do as said before. N/A engine timing for altitude 9 to 9.5 BTDC. You don't show what you have for an air intake filter, pic would be nice. A clear hose from #1 injector back to the filter, for air intrusion. A pyrometer for EGT. If you run it much, keep an eye on the oil level. Are you certain you have the lines from the IP going to the correct injectors? Pic.

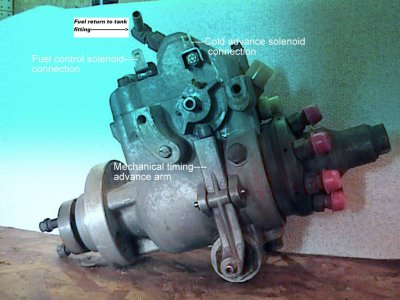

An IP has only two wires on top of it, one for the FSS (Fuel Shutoff Solenoid) closest to the rad, and one for the CAS (Cold Advance Solenoid), the other wires (3) are for the TPS (Throttle Position Sensor) mounted on the side of the IP. If there is a module of some sort mounted on the front of the IP by the fuel inlet and a wire going to it that could be an Altitude compensator, never seen one, but have heard of them. IP Pic below shows connection.

All that said don't solve your problem. But your just going in circles and not achieving nothing. You'll never get it right unless you do as said before. N/A engine timing for altitude 9 to 9.5 BTDC. You don't show what you have for an air intake filter, pic would be nice. A clear hose from #1 injector back to the filter, for air intrusion. A pyrometer for EGT. If you run it much, keep an eye on the oil level. Are you certain you have the lines from the IP going to the correct injectors? Pic.

An IP has only two wires on top of it, one for the FSS (Fuel Shutoff Solenoid) closest to the rad, and one for the CAS (Cold Advance Solenoid), the other wires (3) are for the TPS (Throttle Position Sensor) mounted on the side of the IP. If there is a module of some sort mounted on the front of the IP by the fuel inlet and a wire going to it that could be an Altitude compensator, never seen one, but have heard of them. IP Pic below shows connection.

You must be registered for see images

Attachments

fantastic stuff RLD, the measurements your thinking of are probably radians, if you post the numbers as you have them I can convert them for the rest of the readers to use as well. I'd be inclined to tune for 6600 but thats just me. by the way that 3300 ft = 1 kilometer. And I believe radians is the metric equivalent of degrees

I'd be most interested in seeing that info.

Oldster the big tank runs on its own pump. I just got a new vane pump to push unfiltered fuel through the heat exchanger up to the water separator and then on through the filters. Its not as neat a system as I once had but its more efficient this way. IE I designed it wrong, but it looked good. Then as I figured out what I was doing and corrected the flow chart it wasn't laid out as perfectly as original. But it works better. What can I say, maybe once I get all the bugs worked out of it I'll rebuild the tank to reflect all the changes I've made.

As far as timing equipment goes, I don't have any and its not in the budget, once I can afford the stuff then I'll see about doing a better job ob it. For now I'm going to have to work with what I've got. Nothing, and make the best of it.

I'll check my fuel connections but I'm pretty sure that engine wouldn't rev like that if I'd screwed it up, same for the injectors being stuck open or closed. Wouldn't sound as smooth as it does if I'd screwed the pooch.

Thanks for the diagram of what the wires do, that fuel control solenoid, whats that one. Cause if it does what it's name implies then it could have something to do with my issues. Might not be controlling the fuel correctly or something. Could you explain the operation of that solenoid a bit, what governs its actions and what its range of adjustment is. Thanks

Just got in from a damn long night out so I'll likely be incommunicado for bit after which I'm off to the shop to turn down that fuel.

Oh, one more thing. If that mark on the block indicates 8.5 and the mark on the IP is accurate, then it stands to reason that if I line em up I'll be at 8.5. I'm about 1/16 to the right of that mark on the block with the mark on the pump. If that means anything. I'm thinking that would indicate that I'm a tad ahead. But I don't know exactly how much. Hoping its in the 9.5 range.

I'd be most interested in seeing that info.

Oldster the big tank runs on its own pump. I just got a new vane pump to push unfiltered fuel through the heat exchanger up to the water separator and then on through the filters. Its not as neat a system as I once had but its more efficient this way. IE I designed it wrong, but it looked good. Then as I figured out what I was doing and corrected the flow chart it wasn't laid out as perfectly as original. But it works better. What can I say, maybe once I get all the bugs worked out of it I'll rebuild the tank to reflect all the changes I've made.

As far as timing equipment goes, I don't have any and its not in the budget, once I can afford the stuff then I'll see about doing a better job ob it. For now I'm going to have to work with what I've got. Nothing, and make the best of it.

I'll check my fuel connections but I'm pretty sure that engine wouldn't rev like that if I'd screwed it up, same for the injectors being stuck open or closed. Wouldn't sound as smooth as it does if I'd screwed the pooch.

Thanks for the diagram of what the wires do, that fuel control solenoid, whats that one. Cause if it does what it's name implies then it could have something to do with my issues. Might not be controlling the fuel correctly or something. Could you explain the operation of that solenoid a bit, what governs its actions and what its range of adjustment is. Thanks

Just got in from a damn long night out so I'll likely be incommunicado for bit after which I'm off to the shop to turn down that fuel.

Oh, one more thing. If that mark on the block indicates 8.5 and the mark on the IP is accurate, then it stands to reason that if I line em up I'll be at 8.5. I'm about 1/16 to the right of that mark on the block with the mark on the pump. If that means anything. I'm thinking that would indicate that I'm a tad ahead. But I don't know exactly how much. Hoping its in the 9.5 range.

Thanks for the diagram of what the wires do, that fuel control solenoid, whats that one. Cause if it does what it's name implies then it could have something to do with my issues. Might not be controlling the fuel correctly or something. Could you explain the operation of that solenoid a bit, what governs its actions and what its range of adjustment is. Thanks

The fuel control solenoid does not "control" anything, it just turns the fuel ON and OFF, there is NO adjustment to it.

Oh, one more thing. If that mark on the block indicates 8.5 and the mark on the IP is accurate, then it stands to reason that if I line em up I'll be at 8.5. I'm about 1/16 to the right of that mark on the block with the mark on the pump. If that means anything. I'm thinking that would indicate that I'm a tad ahead. But I don't know exactly how much. Hoping its in the 9.5 range

Please refer to the IP mark as to the "passenger" or "driver" side. If you are facing the IP from the front of the truck and the mark on the IP is to the "right" towards the "drivers" side, then the IP timing is retarded. Turning the IP mark towards the "passenger" side will advance the IP timing. Each and every IP is different, That mark on the IP is "marked" after the engine is run and timed at the factory, it is only a starting point when the IP is changed from engine to engine.

To understand what happens when adjusting the fuel screw, look at the pic's below. The screw is broke from turning it in to far, also the drive shaft is sheared. The screw adjust's (offset's) the C ring, which adjust's the two rollers on the ends of the C ring for more or less fuel. The 1st and 2nd pic, shows the screw head broke off and the end of the shaft sheared.

That adjusting screw, IIRC is a 10-32. So each one sixth (1-hex) equals ~.005 thousands in or out, a full turn would be about a 1/32".

Attachments

OK so just back from the shop and I got a little tricky with it, but it seems to be working out. Vast improvement by turning down the fuel. So here's what I did.

my logic was that the fuel was turned way up and the engine wasn't getting enough oxygen to burn it all. So I had unburned fuel in the exhaust pipes. I'm also inclined to listen when someone tells me to watch out turning "up" the fuel cause it can overheat things. Still not sure how that works but hint taken. So I turned it down, a lot. My thinking on this was that if it was turned up past the point where it could burn all the fuel then it was probably past the point of damaging the engine by being up "to" high. I wanted to turn it down past the point were it would damage something and into the lean range. Someone mentioned, several folks actually that the diesel engine doesn't heat when the engine runs lean it heats when the engine runs rich, and mine was running super rich, so much so that it might have been the unburned fuel that was keeping temps down.

I turned it down ~180° or three flats on the wrench. I have significantly more power and I'm blowing white smoke. Which I can't remember if that means lean or not but I think it does. I took it for a test spin and it most definitely had more power. I also set the timing slightly to the passenger side of the mark.

Forgot the camera tho. So no film today.

Its livable until I get the pyrometer installed, which might be a while cause I just don't have any more money to throw at this thing right now.

All in all a very successful day, didn't even spill much fuel on my nice clean engine.

question for today is, what does white smoke indicate?

my logic was that the fuel was turned way up and the engine wasn't getting enough oxygen to burn it all. So I had unburned fuel in the exhaust pipes. I'm also inclined to listen when someone tells me to watch out turning "up" the fuel cause it can overheat things. Still not sure how that works but hint taken. So I turned it down, a lot. My thinking on this was that if it was turned up past the point where it could burn all the fuel then it was probably past the point of damaging the engine by being up "to" high. I wanted to turn it down past the point were it would damage something and into the lean range. Someone mentioned, several folks actually that the diesel engine doesn't heat when the engine runs lean it heats when the engine runs rich, and mine was running super rich, so much so that it might have been the unburned fuel that was keeping temps down.

I turned it down ~180° or three flats on the wrench. I have significantly more power and I'm blowing white smoke. Which I can't remember if that means lean or not but I think it does. I took it for a test spin and it most definitely had more power. I also set the timing slightly to the passenger side of the mark.

Forgot the camera tho. So no film today.

Its livable until I get the pyrometer installed, which might be a while cause I just don't have any more money to throw at this thing right now.

All in all a very successful day, didn't even spill much fuel on my nice clean engine.

question for today is, what does white smoke indicate?

Last edited:

OK so I just read up on white smoke, worst case it blow by and my engines is worn. But its typically something simple. Like when I parked it to start this process I knew it was due for an oil change. I didn't know I was supposed to use special heavy duty oil in this thing, so its got the cheap stuff in it. Probably whats causing the white smoke or at least a healthy portion of it. So I'm going to try an oil change and use the suggestions made by Oldster (#11 great post by the way ) over here http://www.oilburners.net/forums/showthread.php?t=52813&highlight=white+smoke

I'm thinking some descent oil is next on my list of things to do.

I'm sneaking up on it. Just wrote a contract for some work I'll likely get. If I do it means I can install that pyrometer we've been talking about. And get the timing devise

I'm thinking some descent oil is next on my list of things to do.

I'm sneaking up on it. Just wrote a contract for some work I'll likely get. If I do it means I can install that pyrometer we've been talking about. And get the timing devise

icanfixall

Official GMM hand model

White smoke means we have a new Pope...

It means there is some unburned fuel in the exhaust...

It means there is some unburned fuel in the exhaust...

rhkcommander

Full Access Member

I'm gonna second the motion for ******* injectors...

Hmmmmmm

I turned it down 3 flats, or 180 degrees, if white smoke means there is still some unburned fuel then I should turn it down one more, and see what happens. I thought black smoke meant there was to much fuel?

I'll change the oil first and then go for a spin, if its still blowing white when I stomp on it then I'll keep that spin short so as to not cause any heat damage ( I hope ) and turn it down more.

I'll know in the next couple of days or so if I got that contract. Which will mean I can or can't get the proper measuring tools to help tune this thing.

I turned it down 3 flats, or 180 degrees, if white smoke means there is still some unburned fuel then I should turn it down one more, and see what happens. I thought black smoke meant there was to much fuel?

I'll change the oil first and then go for a spin, if its still blowing white when I stomp on it then I'll keep that spin short so as to not cause any heat damage ( I hope ) and turn it down more.

I'll know in the next couple of days or so if I got that contract. Which will mean I can or can't get the proper measuring tools to help tune this thing.

Fordsandguns

Fords Rule

You might try advancing the timing a little again since you've turned the fuel down. Since you turned down the fuel and still have the white smoke I think it could be timing or injectors or both. Retarded timing can cause the whitish smoke like you describe . So can leaking injectors.

What does the smoke smell like?

What does the smoke smell like?

Black dawg

Registered User

still blowing WHITE smoke?

I would suggest that you quit messing with the fuel screw or you will never know what the factory setting was. That setting was set with a very costly machine that measures the cubic centimeters. Until you have the timing set close for proper engine operation and know what it is, then you can adjust the fuel screw to achieve a good running engine. You backed off the fuel, now you have white smoke, that indicates the timing is retarded. One degree in timing advanced or retarded makes one a hell of a difference.

redneckaggie

rebel w/o a cause

ok im about fed up with this thread because logic is completely null and void from it but I will try to contribute some more

SMOKE COLORS

black-partially burnt fuel to much fuel for the amount of air

White-could be coolant or completely unburnt fuel smell to make sure- usually timing or injector related

blueish white-oil

now about that white smoke, you said you filled the filter and ip with oil to prime it, was this wmo or fresh oil, if wmo you could have cruded up your injectors and there is your white smoke problem.

the fuel screw

QUIT TOUCHING IT

I put this in my earlier post but apparently you didnt catch it, that screw adjust how much fuel is injected on the top end, I have that screw up 4 flats and generally never see smoke just have to be easier on the go pedal(ie dont floor it just gradually push in). the rpm is fuel governed on these trucks so with x amount of fuel you should be at y rpm

This means that the fuel screw does not change the amount of fuel injected at a certain rpm but rather changes the amount of fuel injected at a given throttle postition.

If you think of your fuel delivery as a linear graph IN RELATION TO THROTTLE POSITION turning that screw clockwise only makes the slope of the curve steeper it does not actually shift the whole curve horizontally or vertically.

your pump will twist more that what you think it will, you might have to loosen injection lines, There is no possible way that I see to be pumping enough fuel through the engine to have liquid fuel in your exhaust

are you positive the pump and injectors you put in are good?

These things are not gassers there is no choke. extra fuel does not bog them down and make them run worse unless it is a rediculous amount or injected at the wrong time.

In your video you snapped the throttle up and I saw almost no BLACK smoke out of the tailpipe, just white and as the explanation above suggests that is timing or injector or ip calibration(NOT THE FUEL SCREW) related

SMOKE COLORS

black-partially burnt fuel to much fuel for the amount of air

White-could be coolant or completely unburnt fuel smell to make sure- usually timing or injector related

blueish white-oil

now about that white smoke, you said you filled the filter and ip with oil to prime it, was this wmo or fresh oil, if wmo you could have cruded up your injectors and there is your white smoke problem.

the fuel screw

QUIT TOUCHING IT

I put this in my earlier post but apparently you didnt catch it, that screw adjust how much fuel is injected on the top end, I have that screw up 4 flats and generally never see smoke just have to be easier on the go pedal(ie dont floor it just gradually push in). the rpm is fuel governed on these trucks so with x amount of fuel you should be at y rpm

This means that the fuel screw does not change the amount of fuel injected at a certain rpm but rather changes the amount of fuel injected at a given throttle postition.

If you think of your fuel delivery as a linear graph IN RELATION TO THROTTLE POSITION turning that screw clockwise only makes the slope of the curve steeper it does not actually shift the whole curve horizontally or vertically.

your pump will twist more that what you think it will, you might have to loosen injection lines, There is no possible way that I see to be pumping enough fuel through the engine to have liquid fuel in your exhaust

are you positive the pump and injectors you put in are good?

These things are not gassers there is no choke. extra fuel does not bog them down and make them run worse unless it is a rediculous amount or injected at the wrong time.

In your video you snapped the throttle up and I saw almost no BLACK smoke out of the tailpipe, just white and as the explanation above suggests that is timing or injector or ip calibration(NOT THE FUEL SCREW) related

Last edited:

ok im about fed up with this thread because logic is completely null and void from it but I will try to contribute some more

SMOKE COLORS

black-partially burnt fuel to much fuel for the amount of air

White-could be coolant or completely unburnt fuel smell to make sure- usually timing or injector related

blueish white-oil

now about that white smoke, you said you filled the filter and ip with oil to prime it, was this wmo or fresh oil, if wmo you could have cruded up your injectors and there is your white smoke problem.

the fuel screw

QUIT TOUCHING IT

I put this in my earlier post but apparently you didnt catch it, that screw adjust how much fuel is injected on the top end, I have that screw up 4 flats and generally never see smoke just have to be easier on the go pedal(ie dont floor it just gradually push in). the rpm is fuel governed on these trucks so with x amount of fuel you should be at y rpm

This means that the fuel screw does not change the amount of fuel injected at a certain rpm but rather changes the amount of fuel injected at a given throttle postition.

If you think of your fuel delivery as a linear graph IN RELATION TO THROTTLE POSITION turning that screw clockwise only makes the slope of the curve steeper it does not actually shift the whole curve horizontally or vertically.

your pump will twist more that what you think it will, you might have to loosen injection lines, There is no possible way that I see to be pumping enough fuel through the engine to have liquid fuel in your exhaust

are you positive the pump and injectors you put in are good?

These things are not gassers there is no choke. extra fuel does not bog them down and make them run worse unless it is a rediculous amount or injected at the wrong time.

In your video you snapped the throttle up and I saw almost no BLACK smoke out of the tailpipe, just white and as the explanation above suggests that is timing or injector or ip calibration(NOT THE FUEL SCREW) related

Exactly.

Similar threads

- Replies

- 26

- Views

- 2K

- Replies

- 33

- Views

- 4K

- Replies

- 4

- Views

- 391