You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trailered home a 1989 F350 dump truck that looks great on the outside, but the 7.3 IDI is something else

- Thread starter crazydane

- Start date

IDIBRONCO

IDIBRONCO

But what really caught my eye, was this huge chunk of cylinder wall missing in #8:

At my best guess that is from the wristpin rubbing on the cylinder wall. It's the only thing that I know of that would cause the rounded out pattern at the top. This was right next to completely grenading if that's the case.That thing is a good 1/16" deep. I have no idea where it went. You can also see a crack in the cylinder wall to the right of the missing chunk.

GO BUY IT!!! At least get in touch with the seller ASDAP and make an arrangement to pick it up. This is no longer a hone and rering on you current engine. The crack in the cylinder wall also could explain the milkshake inside the engine. THIS is why I suggested just pulling the engine and opening it up instead of doing a compression or leak down test. This block may not be junk. It may be possible to sleeve the two bad cylinders. Expensive, yes, but it would save another block. I'm not suggesting that you resleeve it now or ever, but it may be savable. If you're going to scrap the engine, at least save what internals that you can and just scrap the block.Here's a running 89 7.3 for $800:

Wristpin rubbing the cylinder wall makes sense. But yeah, this block would require machine shop work at the very least. Tried pining that guy with the running motor for $800 but haven't heard back.

Looking around at places that sells rebuild long blocks, it seems they all charge between $700 to over $1000 for the core, so I have to wonder what issues this "running" 7.3 might have?

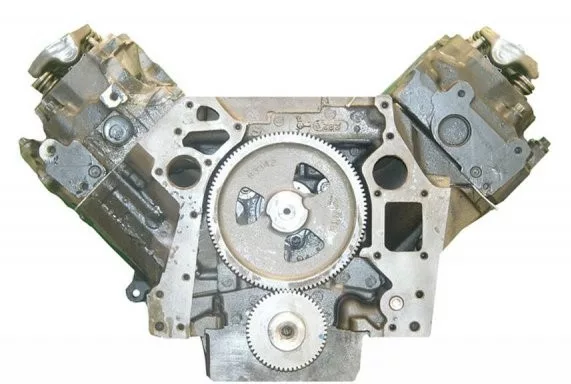

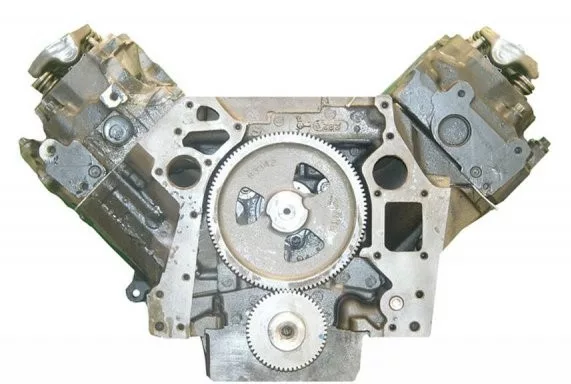

Does anyone here have any experience with Unite Engine? They sell a remanufactured long block for $3,195.

Looks like they do a pretty thorough job:

All long blocks have, lifters, camshaft, timing chain (belt), timing gears, valve guides ,three angle cut seats, cam, rod and main

bearings, pistons, piston rings, rod bushings (if applicable), gaskets and oil pump.

All cylinder blocks, cylinder heads, crankshafts and connecting rods are cleaned and shot peened and magnafluxed for cracks. All bolt holes are tapped.

All oil galleys are hand brushed with white cleaning brushes and cylinders are hand cleaned with cleaning solution .

Cylinder heads have seats cut three angle. After assembly, heads are vacuum checked for valve seating.

Crankshafts are ground and polished . Each oil galley is hand brushed .

All connecting rods are honed.

ALL OUR REMANUFACTURED LONG BLOCKS MEET OR EXCEED ORIGINAL EQUIPMENT SPECIFICATIONS

Engines remanufactured by our remanufacturing line meet or exceed O.E.M. specifications.

– New Pistons (USA)

– New RINGS (USA )

– New S A gear timing gears and chain(USA)

– New MELLING oil pump

– New VICTOR

– Cylinder heads are Rebuilt

– Three angle cut valve seats

– All heads are cnc surfaced

– Blocks are bored, cylinder walls are honed

– Crankshafts are ground and polished

– Camshafts are ground to O.E.M. specifications, hardened and polished

– Connecting rods are resized to O.E.M. specifications

I don't know if existing long block would qualify as a core ($900 from United Engine). The requirements are:

--- cut ---

CORE POLICY : You have 30 days from date of original purchase to return a matching core (rebuildable). Cores must be complete will all its parts including rods, bolts, and must not be cracked. The crank must clear 20/20 and the block must clear .030 for refund.

--- cut ---

They are West Coast, so shipping to VA is likely pretty expensive, as would returning the core, assuming they would accept it. So just scrapping the core, I'd be looking at $4095 plus shipping. But then I'd have an engine that would likely outlast the truck.

More than I was hoping to spend, but given the rest of the truck and dump bed are in excellent shape, perhaps it would be worth it?

I'll call around to some local machine shops to see what they have to say and if, by change, one of them happen to have a 7.3 block in good shape laying around.

Looking around at places that sells rebuild long blocks, it seems they all charge between $700 to over $1000 for the core, so I have to wonder what issues this "running" 7.3 might have?

Does anyone here have any experience with Unite Engine? They sell a remanufactured long block for $3,195.

7.3 FORD IDI 1988-93 REMANUFACTURED DIESEL LONG BLOCK ENGINE WITH OIL PUMP AND GASKETS PLUS A 900.00 CORE DEPOSIT REQUIRED - United Engine Rebuilding

7.3 FORD IDI DIESEL REMANUFACTURED LONG BLOCK ENGINE . FORD F SERIES AND INTERNATIONAL TRUCKS AND BUSSES

unitedengine.com

Looks like they do a pretty thorough job:

All long blocks have, lifters, camshaft, timing chain (belt), timing gears, valve guides ,three angle cut seats, cam, rod and main

bearings, pistons, piston rings, rod bushings (if applicable), gaskets and oil pump.

All cylinder blocks, cylinder heads, crankshafts and connecting rods are cleaned and shot peened and magnafluxed for cracks. All bolt holes are tapped.

All oil galleys are hand brushed with white cleaning brushes and cylinders are hand cleaned with cleaning solution .

Cylinder heads have seats cut three angle. After assembly, heads are vacuum checked for valve seating.

Crankshafts are ground and polished . Each oil galley is hand brushed .

All connecting rods are honed.

ALL OUR REMANUFACTURED LONG BLOCKS MEET OR EXCEED ORIGINAL EQUIPMENT SPECIFICATIONS

Engines remanufactured by our remanufacturing line meet or exceed O.E.M. specifications.

– New Pistons (USA)

– New RINGS (USA )

– New S A gear timing gears and chain(USA)

– New MELLING oil pump

– New VICTOR

– Cylinder heads are Rebuilt

– Three angle cut valve seats

– All heads are cnc surfaced

– Blocks are bored, cylinder walls are honed

– Crankshafts are ground and polished

– Camshafts are ground to O.E.M. specifications, hardened and polished

– Connecting rods are resized to O.E.M. specifications

I don't know if existing long block would qualify as a core ($900 from United Engine). The requirements are:

--- cut ---

CORE POLICY : You have 30 days from date of original purchase to return a matching core (rebuildable). Cores must be complete will all its parts including rods, bolts, and must not be cracked. The crank must clear 20/20 and the block must clear .030 for refund.

--- cut ---

They are West Coast, so shipping to VA is likely pretty expensive, as would returning the core, assuming they would accept it. So just scrapping the core, I'd be looking at $4095 plus shipping. But then I'd have an engine that would likely outlast the truck.

More than I was hoping to spend, but given the rest of the truck and dump bed are in excellent shape, perhaps it would be worth it?

I'll call around to some local machine shops to see what they have to say and if, by change, one of them happen to have a 7.3 block in good shape laying around.

IDIBRONCO

IDIBRONCO

I believe that United has been around for a long time now. I don't know anything about their IDIs though. The only way to know if your engine would be accepted as a core would be to call them. Would it be worth the cost? Only you can answer that one. Don't give up on the FB one yet. Sometimes it takes people a while to answer back.

Old Goat

Full Access Member

Then you need to remove the Transmission, Clutch and FW.It probably isn't... yet. But when will it ever be easier to replace? And think about what you'd have to do over again to replace it in a few years. Or days...

I just went through this. I could not get a Socket with extension on the 2 top Bell Housing Bolts. Had to cut the Pinch Weld in 2 places and bend back.

Looking back on it, I think it is because the Cab mounts are long gone, and the Cab has dropped down.

Goat

ttman4

Last Nite's Dream..

- Joined

- Oct 31, 2005

- Posts

- 1,110

- Reaction score

- 641

How big is your shop? How wide & long & hi?@XOLATEM Thanks. Yeah, the views here are fantastic:

You must be registered for see images attach

And I just got done hanging drywall over the last 6 months or so. Turned out nice and is so much brighter than before with the exposed insulation:

You must be registered for see images attach

It's my little place to get away from it all and tinker with my projects!

Once I get the heads off, I'll check that they are the block are straight. If not, I'll be looking for a machine shop. Place I used to use is closed down, but there are a couple of others I will check out.

I'm VERY VERY envious as to how clean it is!!!!!!

I have one rented up town for bout 12 yrs & when I've cleaned, swept, put tools up it still looks like the city dump!!!

Im in process of building one here at home. A 40x64 with 14' walls, 1 14x14 overhead door on one end & a 14w x 12' hi overhead door on other end. After kit was delivered I thought & thought, then started kicking & kicking & kicking myself for not taking a kit with 16' walls......I could have much better shop!!

Been talking to some junk yards and machine shops today. Found 3 complete engines within 50 miles in unknown conditions for around $500 a pop. They were 89 - 92 7.3s.

Also spoke to a diesel machine shop that has rebuild plenty of these over the years and put in liners, but based on what I told him about mine, he felt getting another block would make the most sense. He didn't have one laying around, but called me back a few hours later as he had a friend with 2 of them.

Spoke to him and one he is going to rebuild himself once he finds the time, the other he was willing to sell me. It's still in a 1992 truck that burned in a house fire. So the long block itself should be just fine. He thought it was a F350 dually 4x4, but wasn't 100% sure since it was 3 years ago he acquired it. It ran great before the fire he said. He paid $1,500 for it and would sell it to me for the same.

Going to look at it Saturday. I'd love the convert my dump truck to 4x4 since I got some steep hills around my land. It has an automatic however, so I'm not sure if the transfer case would bolt onto my 5 speed or if the front axle (pretty sure it would be a Dana 60), but not sure it it would bolt right up to my 1989 2 wheel drive. I'm sure there are plenty of good drivetrain parts on that truck still, however.

@ttman4 Conditioned part of the shop is 48x30 with 12' walls. It was a kit too. There's a 32x36 addition, also with 12' walls. The shop was clean until I pulled this 1989 dump truck into it and started taking it apart.

Also spoke to a diesel machine shop that has rebuild plenty of these over the years and put in liners, but based on what I told him about mine, he felt getting another block would make the most sense. He didn't have one laying around, but called me back a few hours later as he had a friend with 2 of them.

Spoke to him and one he is going to rebuild himself once he finds the time, the other he was willing to sell me. It's still in a 1992 truck that burned in a house fire. So the long block itself should be just fine. He thought it was a F350 dually 4x4, but wasn't 100% sure since it was 3 years ago he acquired it. It ran great before the fire he said. He paid $1,500 for it and would sell it to me for the same.

Going to look at it Saturday. I'd love the convert my dump truck to 4x4 since I got some steep hills around my land. It has an automatic however, so I'm not sure if the transfer case would bolt onto my 5 speed or if the front axle (pretty sure it would be a Dana 60), but not sure it it would bolt right up to my 1989 2 wheel drive. I'm sure there are plenty of good drivetrain parts on that truck still, however.

@ttman4 Conditioned part of the shop is 48x30 with 12' walls. It was a kit too. There's a 32x36 addition, also with 12' walls. The shop was clean until I pulled this 1989 dump truck into it and started taking it apart.

IDIBRONCO

IDIBRONCO

It won't. You have to have a 4X4 transmission. The back part of the transmission cases are different. Plus you have some different internals.I'm not sure if the transfer case would bolt onto my 5 speed

Most likely.the front axle (pretty sure it would be a Dana 60),

tbowker

Full Access Member

My shop is 40×60 and 16' to the eaves. I should have listened to a friend who told me to lay two courses of block first and then set the building on the block, that way when you build a loft you don't bang your head when you're in the loft and next to the eaves. I think about it every time I hit my head.How big is your shop? How wide & long & hi?

I'm VERY VERY envious as to how clean it is!!!!!!

I have one rented up town for bout 12 yrs & when I've cleaned, swept, put tools up it still looks like the city dump!!!

Im in process of building one here at home. A 40x64 with 14' walls, 1 14x14 overhead door on one end & a 14w x 12' hi overhead door on other end. After kit was delivered I thought & thought, then started kicking & kicking & kicking myself for not taking a kit with 16' walls......I could have much better shop!!

I watched few videos on doing a 2 wheel to 4 wheel drive conversion on these trucks, and I don't think I'll want to get into all that. Plus I'd have to add 4" blocks in the rear, which I don't think would do me any favors driving a heavy load of gravel down the road in the dump bed. If I do pick up that burned up 92 4x4 F-350, I suspect I can part out the front axle and related components and probably recover a fair amount of the purchase cost.

And with me needing a different transmission to boot, I don't think the conversion would be worth it. But I will more than likely switch to a locker in the rear. My Duramax truck won't make it up this one steep logging road on my properly without a load in the back or being in 4x4. And unless the road is bone dry, forget about it. And the lower part of my property is where I'll be hauling up dirt from.

I believe this truck has a 12 bolt Sterling 10.25" rear axle and I'm thinking an Eaton Detroit Locker would serve me well for keeping the rear locked when hauling dirt up from the lower field.

And with me needing a different transmission to boot, I don't think the conversion would be worth it. But I will more than likely switch to a locker in the rear. My Duramax truck won't make it up this one steep logging road on my properly without a load in the back or being in 4x4. And unless the road is bone dry, forget about it. And the lower part of my property is where I'll be hauling up dirt from.

I believe this truck has a 12 bolt Sterling 10.25" rear axle and I'm thinking an Eaton Detroit Locker would serve me well for keeping the rear locked when hauling dirt up from the lower field.

Last edited:

ironworker40

NYC Ironworker

$3099 $550 core charge 12 hr roundtrip ride or $250 freight

ironworker40

NYC Ironworker

I clicked on the wrong one. I did one and I sent him one of R&D's cams and they put that in it. Others on here have used them also search for Promar I'm sure you will find threads about them. It was a top notch rebuild.

I just realized there price is now $4399 when I did it it was $3000 core is $800 sorry still half asleep

I just realized there price is now $4399 when I did it it was $3000 core is $800 sorry still half asleep

SkylabTech86IDI

Full Access Member

That would be awesome if that's all it is. I'll get the engine cleaned up once the weather gets a little nicer. Been a deep freeze for the last week or so here in Virginia. Given how oily everything is, I do want to redo all the gaskets/seals and pull the engine, but it would be nice to know that it runs at least halfway decent first.

If you’re ever in the South East VA section of the state, then I have a complete DTI timing Kit available to use for timing.

The air filter grommet is known for letting water pool into the intake, caused by a faulty cowl to hood seal. There's a chance the engine is fine. Put fresh fluids in er and see what she does?

I'd try to run it to get any rust off out of the holes, then do a leak down/compression test to check the engine health.

Unless you just want to overhaul it.

FWIW I bought a brand new cowl seal from rock auto for about $60 + shipping. Had to put my own silicone caulk sealant behind it for it to do anything.

Similar threads

- Replies

- 4

- Views

- 756

- Replies

- 4

- Views

- 434

- Replies

- 33

- Views

- 5K

- Replies

- 26

- Views

- 3K