Ferdy Mint

Full Access Member

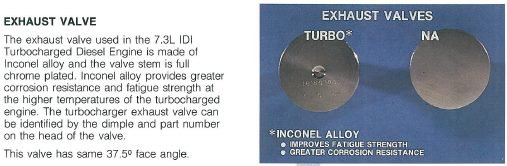

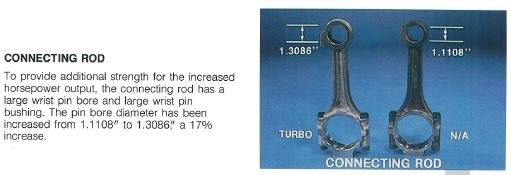

If you have an IDI block you can make it into an IDIT easily. The blocks are the same. Only the rods, wrist pins and pistons are specific to the turbo. I'm not sure about the crank. Both have under-piston oil cooling. There are stories on the internet about webbing in the casting being different, or firing order. But all three of the specialists I talked to said they cannot see any differences at all. I talked to Accurate Diesel, Classic Diesel Designs, and R&D Performance.

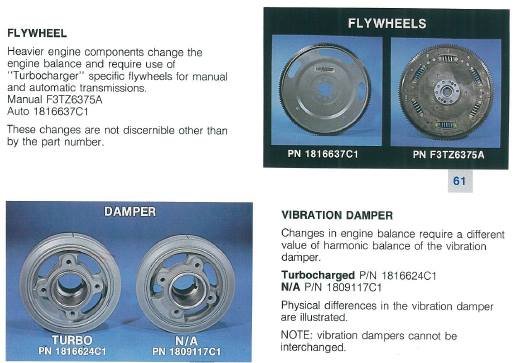

On the other hand, they also said that 10% of the IDI blocks they see have offset cylinder cores, so they strongly recommend sleeving any IDI you rebuild. My local machine shop only charges $60 per cylinder to sleeve. So if you've been looking for an IDIT truck for years, just build your own instead. The vibration damper, flywheel and clutch need to be turbo versions too.

R&D sells forged 7.3 PSD rods that are machined to fit an IDIT. FYI

On the other hand, they also said that 10% of the IDI blocks they see have offset cylinder cores, so they strongly recommend sleeving any IDI you rebuild. My local machine shop only charges $60 per cylinder to sleeve. So if you've been looking for an IDIT truck for years, just build your own instead. The vibration damper, flywheel and clutch need to be turbo versions too.

R&D sells forged 7.3 PSD rods that are machined to fit an IDIT. FYI

ive tried.

ive tried.