You must be registered for see images attach

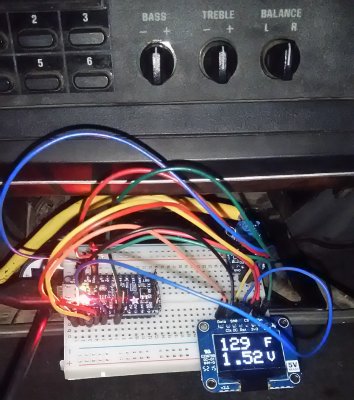

I didn't really like the Banks gauge... so, ta daaaa! It's about $40 in parts, with the screen being half of that. The enclosure is up to your imagination. You can change it from *F to *C in the code, and can see the actual voltage from the pyro-amp output. Obviously it'd be really compact without the breadboard. Truck was off for a bit, so it's reading residual heat after a test run prior to the photo.

Wiring is pretty simple... I'll work up a diagram in the future. Right now it's powered by USB in it's prototype form, but it can easily take a key-on 12v source.

Basic Parts:

Adafruit Pro Trinket (5v)

128x64 OLED

For Pyro Readout:

K Type Thermocouple Amp

For Boost Readout:

MPX 4250DP (36 PSI boost max measurement capability)

EDIT: Code updated to display average of 10 samples

Arduino Sketch:

Code:

[SIZE=1]

#include <SPI.h>

#include <Wire.h>

#include <Adafruit_GFX.h>

#include <Adafruit_SSD1306.h>

// If using software SPI (the default case):

#define OLED_MOSI 9

#define OLED_CLK 10

#define OLED_DC 11

#define OLED_CS 12

#define OLED_RESET 13

Adafruit_SSD1306 display(OLED_MOSI, OLED_CLK, OLED_DC, OLED_RESET, OLED_CS);

#define XPOS 0

#define YPOS 1

#define DELTAY 2

int convertTemp = 0;

float convertPSI = 0;

const int numReadingsPSI = 10;

int readingsPSI[numReadingsPSI]; // the readings from the analog input

int readIndexPSI = 0; // the index of the current reading

int totalPSI = 0; // the running total

int averagePSI = 0; // the average

const int numReadingsPYRO = 10;

int readingsPYRO[numReadingsPYRO]; // the readings from the analog input

int readIndexPYRO = 0; // the index of the current reading

int totalPYRO = 0; // the running total

int averagePYRO = 0; // the average

void setup() {

display.begin(SSD1306_SWITCHCAPVCC);

display.clearDisplay();

display.setTextSize(3);

display.setTextColor(WHITE);

display.setTextSize(4);

for (int thisReadingPSI = 0; thisReadingPSI < numReadingsPSI; thisReadingPSI++) {

readingsPSI[thisReadingPSI] = 0;

}

for (int thisReadingPYRO = 0; thisReadingPYRO < numReadingsPYRO; thisReadingPYRO++) {

readingsPYRO[thisReadingPYRO] = 0;

}

}

void loop() {

//AVERAGE PSI

// subtract the last reading:

totalPSI = totalPSI - readingsPSI[readIndexPSI];

// read from the sensor:

readingsPSI[readIndexPSI] = analogRead(A0);

// add the reading to the total:

totalPSI = totalPSI + readingsPSI[readIndexPSI];

// advance to the next position in the array:

readIndexPSI = readIndexPSI + 1;

// if we're at the end of the array...

if (readIndexPSI >= numReadingsPSI) {

// ...wrap around to the beginning:

readIndexPSI = 0;

averagePSI = totalPSI / numReadingsPSI;

}

//AVERAGE PYRO

// subtract the last reading:

totalPYRO = totalPYRO - readingsPYRO[readIndexPYRO];

// read from the sensor:

readingsPYRO[readIndexPYRO] = analogRead(A1);

// add the reading to the total:

totalPYRO = totalPYRO + readingsPYRO[readIndexPYRO];

// advance to the next position in the array:

readIndexPYRO = readIndexPYRO + 1;

// if we're at the end of the array...

if (readIndexPYRO >= numReadingsPYRO) {

// ...wrap around to the beginning:

readIndexPYRO = 0;

averagePYRO = totalPYRO / numReadingsPYRO;

}

//DISPLAY START

display.clearDisplay();

convertTemp = (((averagePYRO*(5.0/1023.0)-1.25)/.005)*9/5+32);

convertPSI = (((averagePSI*(5.0/1023)/.01845)-9)*0.14503773773020923);

display.setCursor(12,0);

display.println(convertTemp);

if (convertPSI<9.999)

{

display.setCursor(36,34);

}

else

{

display.setCursor(12,34);

}

display.println(abs(convertPSI),1);

display.display();

}

[/SIZE]Attachments

Last edited: