180º out with a 6.2 pump or run two regular 6.9 pumps with a custom gear housing and the pumps sitting side by side: then they rotate the same as always and are gear driven still. like a Y.

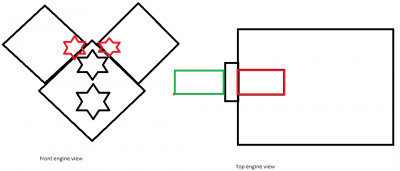

Drew a crappy picture in paint really quickly to display the two possibilities. The first one would be using two normal DB2s, and a custom oil- fillport / gear housing for the IPs. We'd need a second ip, gear, and a custom housing made. The two pumps would be offset from the center, their gears would touch the other one like normal - not each other. therefore rotating the same. picture is of the gears, cant remember if i got them all lol but red=db2 gears.

Second picture is a top down, with a regular db2 in red in regular mounting position, and a green GM DB2 in green mounted opposite of the ford DB2. the original housing might be adaptible to this idea, it wouldn't be as pretty but would be easier/cheaper on the housing. fuel lines would be longer but either way we'd need custom ones... I'd prefer the double pumps in a Y config with gearing. Anothe random google image - the top two would be IP gears

http://www.freshpepper.net/wp-content/uploads/2012/12/gears.png

Only time they wouldn't spin the same is if you stacked them one atop the other

Imagine dual mooses, 180-200cc with moose reliability. then a fat turbo or maybe twins

. Wouldn't worry about bottom half any, maybe a girdle just cause. Clean rebuild done well is going to cost about 2-3000$, either going for performance/reliability or bone stock. Ceramicoat the pistons, peen/cryo stuff, cam grind, studs, improved exhaust, intercooler either air-air or air-liquid, increase oil pressure, etc definitely not as much as some quote... I could see up to 10k on the whole drivetrain if going for perfection across the board. Haven't heard of very many instances of low end damage, except someone running insane amounts of methanol injection... We have a lot more to work with than the 6.2 crowd. Any inline 6 should be more stout, they have 6 pistons in a column whereas we have (double) 4... These engines are old school, pioneers of the diesel light duty trucks. We won't have all the bells and whistles but are blessed with a pretty well designed, durable design. There is always improvements over stock though.

. Wouldn't worry about bottom half any, maybe a girdle just cause. Clean rebuild done well is going to cost about 2-3000$, either going for performance/reliability or bone stock. Ceramicoat the pistons, peen/cryo stuff, cam grind, studs, improved exhaust, intercooler either air-air or air-liquid, increase oil pressure, etc definitely not as much as some quote... I could see up to 10k on the whole drivetrain if going for perfection across the board. Haven't heard of very many instances of low end damage, except someone running insane amounts of methanol injection... We have a lot more to work with than the 6.2 crowd. Any inline 6 should be more stout, they have 6 pistons in a column whereas we have (double) 4... These engines are old school, pioneers of the diesel light duty trucks. We won't have all the bells and whistles but are blessed with a pretty well designed, durable design. There is always improvements over stock though.

. Wouldn't worry about bottom half any, maybe a girdle just cause. Clean rebuild done well is going to cost about 2-3000$, either going for performance/reliability or bone stock. Ceramicoat the pistons, peen/cryo stuff, cam grind, studs, improved exhaust, intercooler either air-air or air-liquid, increase oil pressure, etc definitely not as much as some quote... I could see up to 10k on the whole drivetrain if going for perfection across the board. Haven't heard of very many instances of low end damage, except someone running insane amounts of methanol injection... We have a lot more to work with than the 6.2 crowd. Any inline 6 should be more stout, they have 6 pistons in a column whereas we have (double) 4... These engines are old school, pioneers of the diesel light duty trucks. We won't have all the bells and whistles but are blessed with a pretty well designed, durable design. There is always improvements over stock though.