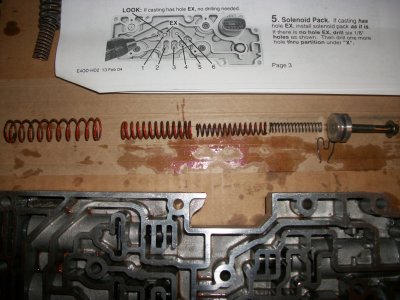

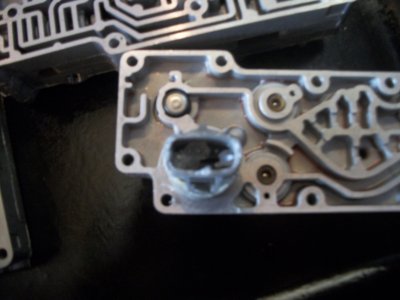

ah nuts.my bad on this one! better check them instructions.i was having such a good time,i was forgetting i was taking pics.i had installed the first part of this assembly here.once installed (it was a bit of a ****** so i didn't want to pull it for the pic lmao.sorry!) i then snapped ya one.

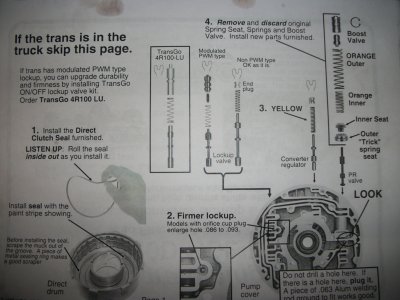

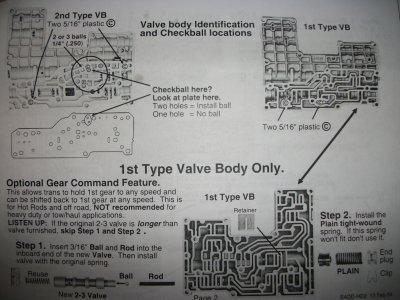

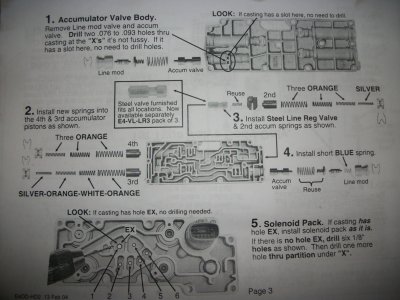

basically though what i missed to show,was replacing that regulator valve.the oem one was a bright colored purple.you replace than with the new steel one supplied in the kit.reuse the little spring and then set that clip back in (yeah i had this all done when i remembered the cam right here.no biggie.the instructions are clear.) then simply install the springs as shown.

install blue spring as noted in step 4 of instructions.final mod of accumulator.

your adding this short blue spring where there was no spring at all currently.

(find this particular short blue spring in the same pack of the other accumulator springs.not to be confused with a blue spring in other package.)

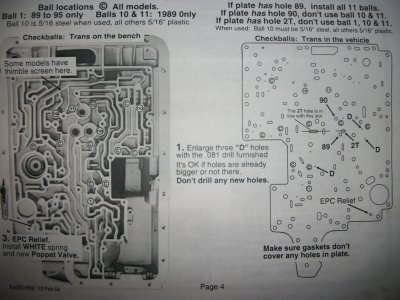

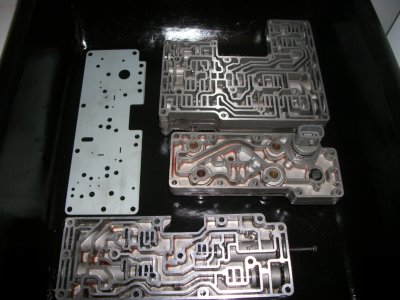

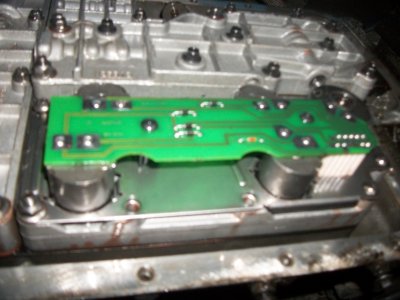

moving on to the solenoid pack modifications.

notice the EX hole in my pack.no drilling required.see all those slots as well compared to the instructions? see how all those are able to flow atf through there.

additional.take note

this great time to clean the s pack pins.

this is the main line of communication between the trans controller and your transmission.these pins can't be over clean.take your time and make them shine.

upon reasonably,just before plugging it in,apply a nice dose of Permatex 22058 dielectric tune-up grease.

side note and pic;

check out this pic.here is a pack i pulled from my f250 (i had to replace that due to extremely corrosive pack plug that i just couldn't ever get clean.) and it doesn't have hole EX.notice how all these passages are full as well.no atf can flow up around there.that s-pack would be one that would require the modifications.

i have a transgo tugger kit installed in that truck (by trans shop during reman) when i went to replace the pack a few months ago,i didn't know to look to see if the new pack i put in required modding.come warm weather i'll take a peek and mod it if needed.

(yeah i know this ones dirty.it's junk.i pulled this out of the junk pile for ya to compare.)

this makes ya wonder, if this was the pack in the trans during a reman with the install of the tugger kit,then why wasn't it modified? the bad electrical pins should have been discovered during the reman as well too anyway,with a new pack going in at this time.it's as if this pack went without proper inspection all the way around by the trans shop unfortunately.

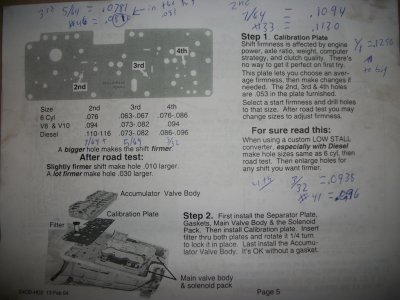

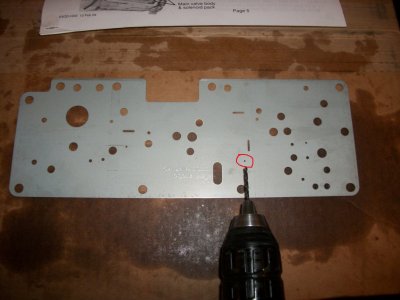

now it's time to figure out what you want for shifts.step it up and make 'em like a man shift.don't girl out now and go too easy ya sissy.so big or go home!

ok.seriously.do be a bit careful.you can always make the holes larger if one or more shifts are bit too girlish still.that requires draining the juice again so do consider an 4r100 pan.

2nd.for diesel .110-116. using a chart i quickly googled,and as you can see i did a little scribbling of what i found here on the sheet.

http://www.carbidedepot.com/formulas-drillsize.htm

i went with a 7/64 drill bit here.

3rd.i used the supplied drill bit (this is the one shown pointing to the holes in the pics.) which is for page 4.it say's it's an .081.yeah it's on the large end of things for this one,plus this old gal has 5:13's uh oh......im not scared,but probably should be lol.

4th.give me a nice firm final shift into OD too.i'll like it.i went with a 3/32 bit here.

this completes the steps i'll be doing for my diesel work truck.the parts are ready to go back in the truck once i perform the instructions on page 4 tomorrow. yes i'll have the pics for ya of course! seriously,you got worried?

stay tuned and keep it right here on channel 444 log truck as i take this E40D sissy shifting slush bucket and transform her into a crisp shifting beast.