Shop Update

Well I built an addition to the back of the shop, (you know we never have enough room) finally got it insulated. I spent the big bucks and got it spray foamed 3". Worth every dime, I will never use traditional insulation again in any type of structure, this stuff is far superior, and has a lifetime warranty. Completely seals from all elements including water, adds strength to the walls. Now its time to move equipment back in so I can continue to work. I am going to take a break today and start Monday.

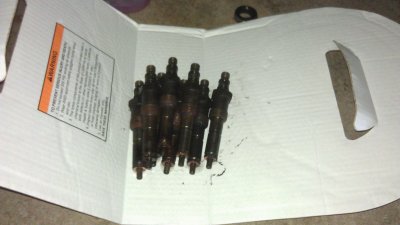

One thing I did do with the 6.9 yesterday, something I should have done in the beginning, took a comp test. Found 2 cylinders in the back at 130 psi, I stopped at that point, the first four I checked had 350psi. With that said I will put in the 7.3 motor to get the truck going and deal with the 6.9 at a later date.

I will need help on the wiring portion. I see the wiring is slightly different from the 6.9, but the 7.3 has the updated glow plug system, not sure if I should keep the 6.9 stuff and put on the 7.3 or use all the 7.3 stuff and splice it in? Even the fuel filter housing is different more connections on the 7.3?

Some specifics would be appreciated on the wiring of this swap. I am going to replace the rear main, valve covers, cooler o ring, the crank seal looks ok, I have to see how difficult it is to replace, I don't know about the water pump? What do you guys recommend since the motor is on the stand now? Head gaskets?