MTKirk

Full Access Member

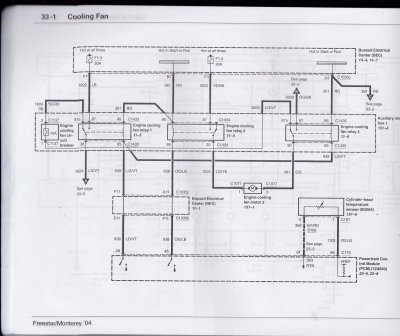

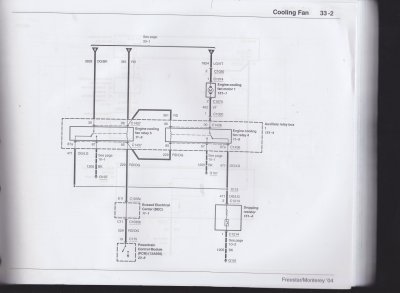

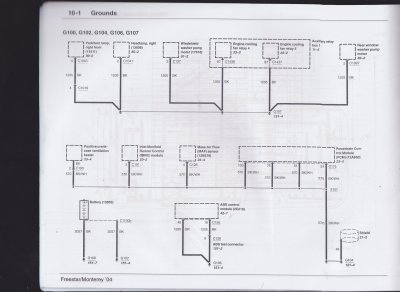

I decided to take the plunge, and go with an electric fan. I have removed my old fan/clutch/shroud combo & have a new doorman dual fan assembly for a 2002 Ford Windstar (only $88 delivered to my door). The fans have two different electrical connectors, the one on the smaller fan is two prongs (12V+ and ground); The larger fan has three prongs (12V+ power, 12V+ power, and ground). In testing the fans I have isolated which is supposed to be positive & which negative (by taking note of which direction the fan blows). On the large fan with three prongs, it appears to make no difference in fan speed if I switch power between the positive tabs, or even if I provide power to both. See attached pic of the connector.

Can anyone tell me if this is accurate & if so which Positive tab(s) should I use on the large fan?

I have a dakota digital electronic fan controller. My plan is to have the small fan come on when coolant temp reaches 215F, if this lowers the temp to 205F the fan will turn off. Should the temperature continue to climb to 220F, the large fan will turn on while the small fan continues to run, when the temp is lowered to below 220F the large fan will turn off and the small fan will continue to run until temp lowers to 205F. The controller has a A/C input wire that will turn on the small fan any time the A/C clutch receives 12+ (regardless of temp, unless the fans are already active because of engine temps.

Any thoughts on these temp values: To low? To high?

I made mounts for the fan out of some structural steel stud scraps I had laying around, They run the full height of the fan shroud, are attached with 8 #9 sheet metal screws with rubber washers (steel roofing screws). I plan to bolt these to the radiator with 6 to 8 1/.4” bolts. This upper part of the shroud provides a tight fit on the upper part of the radiator and is very solid. The bottom 4 or five inches of my radiator extends below the shroud. I’m not particularly concerned with this, the shroud is close enough to the radiator to prevent air being sucked in between the shroud & radiator (without passing through the radiator). I figure that if anything this will give me additional “free” airflow when I reach highway speeds.

Thoughts on this: Is my thinking flawed? Should I work on covering this gap?

Can anyone tell me if this is accurate & if so which Positive tab(s) should I use on the large fan?

I have a dakota digital electronic fan controller. My plan is to have the small fan come on when coolant temp reaches 215F, if this lowers the temp to 205F the fan will turn off. Should the temperature continue to climb to 220F, the large fan will turn on while the small fan continues to run, when the temp is lowered to below 220F the large fan will turn off and the small fan will continue to run until temp lowers to 205F. The controller has a A/C input wire that will turn on the small fan any time the A/C clutch receives 12+ (regardless of temp, unless the fans are already active because of engine temps.

Any thoughts on these temp values: To low? To high?

I made mounts for the fan out of some structural steel stud scraps I had laying around, They run the full height of the fan shroud, are attached with 8 #9 sheet metal screws with rubber washers (steel roofing screws). I plan to bolt these to the radiator with 6 to 8 1/.4” bolts. This upper part of the shroud provides a tight fit on the upper part of the radiator and is very solid. The bottom 4 or five inches of my radiator extends below the shroud. I’m not particularly concerned with this, the shroud is close enough to the radiator to prevent air being sucked in between the shroud & radiator (without passing through the radiator). I figure that if anything this will give me additional “free” airflow when I reach highway speeds.

Thoughts on this: Is my thinking flawed? Should I work on covering this gap?