Cheaper Jeeper

Full Access Member

My truck has a bit too much blowby for my taste, and with the Banks turbo kit it has on it, the CDR is about 3" from the intake side of the compressor wheel of the turbo - between the turbo and the filter. I'm thinking that much oil vapor going into the turbo can't be all that good for it, and it makes me very nervous.

I've tried building 3 different prototype oil vapor traps and like everyone else, I've found that if they trap enough oil to be worth installing, they also create too much back pressure. If they don't create any blowby backpressure they don't trap oil worth a $%&@ either.

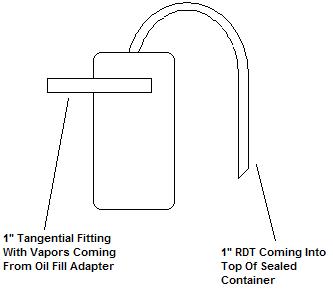

I've looked at the idea of an RDT, but I just don't LIKE the concept. Having smoke (oil vapor) pouring out from under your truck doesn't look any better than having the smoke come out of the tailpipe IMO. Plus the oil is totally wasted - I figure if it's going to get rid of the oil, at least I should try to burn some of it and get some BTUs out of it. Instead of just spitting it out onto the road - which isn't good environmentally. Lastly it makes a mess of the underside of the truck.

So, here's what I'm thinking of doing. I want to use some 3/4" steel pipe fittings to fab a new CDR mount and plumb it to the intake on the OUTSIDE of the air filter - to where the filter would be between the CDR inlet and the turbo compressor. Since I'm using a K&N filter, I figure a fair amount - maybe even most - of the vapor will be trapped in the filter. Since it is an oiled filter, it can't hurt it - just make it self oiling. Whatever does get through the filter will still be going into the engine to be burned.

So what do you think?

I've tried building 3 different prototype oil vapor traps and like everyone else, I've found that if they trap enough oil to be worth installing, they also create too much back pressure. If they don't create any blowby backpressure they don't trap oil worth a $%&@ either.

I've looked at the idea of an RDT, but I just don't LIKE the concept. Having smoke (oil vapor) pouring out from under your truck doesn't look any better than having the smoke come out of the tailpipe IMO. Plus the oil is totally wasted - I figure if it's going to get rid of the oil, at least I should try to burn some of it and get some BTUs out of it. Instead of just spitting it out onto the road - which isn't good environmentally. Lastly it makes a mess of the underside of the truck.

So, here's what I'm thinking of doing. I want to use some 3/4" steel pipe fittings to fab a new CDR mount and plumb it to the intake on the OUTSIDE of the air filter - to where the filter would be between the CDR inlet and the turbo compressor. Since I'm using a K&N filter, I figure a fair amount - maybe even most - of the vapor will be trapped in the filter. Since it is an oiled filter, it can't hurt it - just make it self oiling. Whatever does get through the filter will still be going into the engine to be burned.

So what do you think?