Proceed with caution...

There is a trick to getting it out. Once you have the easy stuff off,

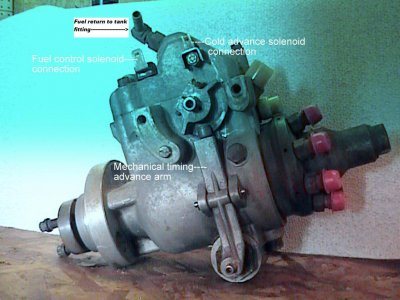

You must be registered for see images attach

Then, see the red cap in the pic in post 3? It has to come off. Loosen the lock nut and remove the pin. You may want to count how many turns in it goes, so you can back it out the same number of turns when you put it back together, or put a spot of paint on it.

Next, take a really good look at the pic in post 3. The little clip on the metering valve sits on top of that pin. Something to note when you're putting it back together.

Now, the spring on the shaft needs to come off. Taking it off is relatively easy. Putting it back on can be a real *****.

Now that the pin it out of the way, just slide that piece the pin was in away from the spring.

With the spring now loose, you can crank the throttle shaft open and the part that has the governor spring will be able to move forward (compressing governor spring), up and out. Be careful though, there is a little spring inside that piece. This is the resistance to the pin. The pin is for fine tuning the governor speed. In = lower, out = higher.

The throttle shaft will now be able to be pulled out.

Reverse the procedure to assemble.

Good luck!