I have seen this problem many times in my work through the years. Hydraulic solenoids will burn up. I had a safety interlock solenoid burn up on a skid steer. I have had many different relays and contactors burn up.

They all get hot and burn up if they are energized and the metal core is not in the middle of the windings. If you are testing a coil on the bench, and you do not have the metal plunger up inside the core, it will burn up for sure.

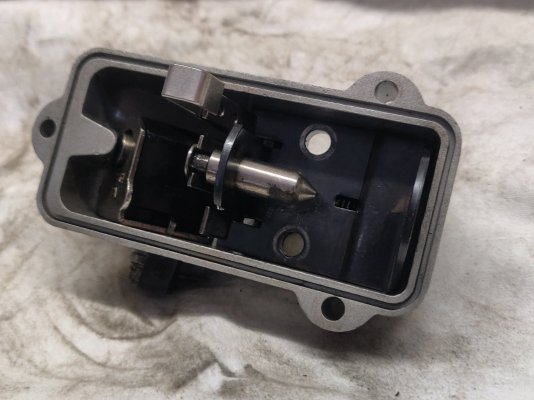

On various hydraulic solenoids I have worked on in factory automation, the spool would occasionally stick and if it was energized long enough, it would smoke the coil and then blow the control fuse.

On the skid steer they had a mechanical interlock on the levers that would lock them from being accidentally moved. One of them got bent, the plunger could not pull it'self all the way up in the middle of the coil, it fried the coil and kept blowing the main harness fuse and it would not run. That was a difficult one to find.

Many many times we have lost a single phase on the 3 phase electrical system. This would sometimes present about 60-70 volts A/C on a 120v ac control. This would not be enough voltage to pull the guts of the contactor into the coil, but would be enough voltage over time to smoke the coil because the coil was empty inside with no metal in it. Would smoke many machine contactors.

I would check and see if there is a problem with your IP, not letting the metal plunger fully insert inside the coil.