I think their point is not that you are not qualified, but that you are not adding any actual data. Like you could just as well be a holiday inn express patron as far as anyone knows.

Precisely my point.

I guess an accumulated total of over 12 million hours of dynamometer Engine Development time under my watch doesn’t count fo much.

Plus supplier work and field test.

What’s your credentials? How many hours have you spent with FelPro or Dana Victor in your office developing head gaskets?

Or did you stay at a Holiday Inn last night?

Come now let's not be foolish. I'm not saying you're WRONG, I'm merely stating that at present you are an unvalidated data set.

If you are indeed who you are IMPLYING you are, then you would be a very welcome and valued member of the community.

If you are indeed who you imply you are, a high level engineer with a long standing career in the industry, then let me put this in more relatable terms.

If a new engineer came up to you and said "this project you have 25,000 hours of flawless test data on has an inherent flaw" what would you do? Would you scrap the whole project because he SAID there's an issue? No, you would say "Show me what data you have collected so that I can verify it".

Nothing wrong with that at all.

How then would you react if he said "Oh no, I've done enough research that my data doesn't need to be questioned"?

I would imagine at that point you would simply laugh and carry on as you were before.

I'm simply saying, please validate your claims as they contradict years of existing data. Which I don't feel should be very difficult for someone with "over 12 million hours of dynamometer Engine Development time".

Being defensive and vague is simply unproductive and unprofessional.

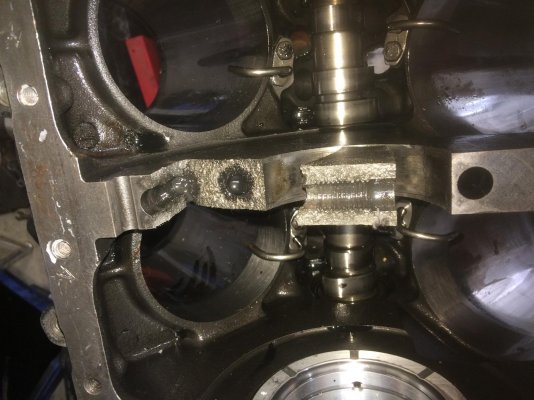

. It’s in extremely good shape.

. It’s in extremely good shape.