TygreII

Registered User

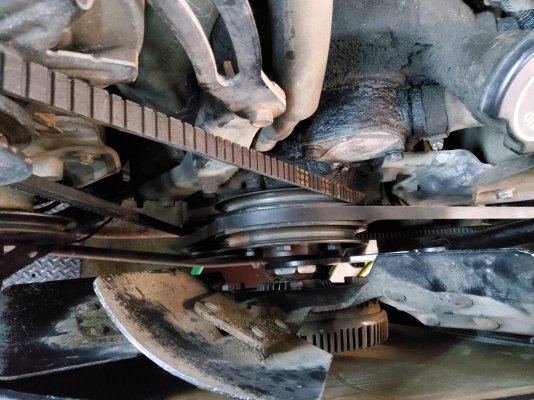

I need ssome additional suggestions. The nut holding the fan on my waterpump is being stubborn.

I've tried: Pnumatic fan clutch wrench (90psi, 4500 hit/second)

PB Blaster

Heat gun

4 lb hammer

I really need to get this done.

Thanks ahead of time

Tygre

I've tried: Pnumatic fan clutch wrench (90psi, 4500 hit/second)

PB Blaster

Heat gun

4 lb hammer

I really need to get this done.

Thanks ahead of time

Tygre