youngunbd

Registered User

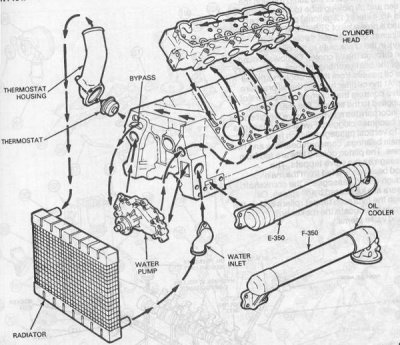

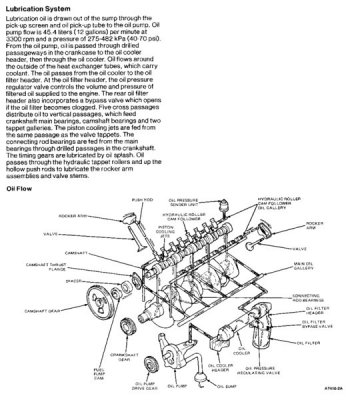

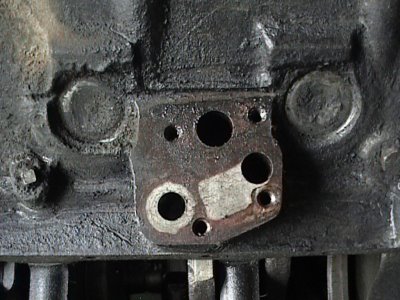

I got curious about reading of oil cooler problems and that it is quite a pain to get to and re-seal. I figure there's got to be an alternative that could possibly work better. I guess the first question is what is the cooling capacity of our current coolers, as in surface area inside a standard oil cooler. I was interested in using something like this:

http://www.ebay.com/itm/30-rows-10A...Parts_Accessories&hash=item3f3018abc1&vxp=mtr

30 row oil cooler with electric fan. I saw one on a D250 similar to this mounted back under the bed between the frame rails, it worked quite well until it's shoddy instillation made it meet highway 80 heh

I have a second oil cooler as a gift from the previous owner of my rig, I might make a copy of it's mount on the CNC and see what can be done about adapting it to an aux cooler.

Another question remains about the coolant that goes through the cooler, would those ports need to be blocked off or should I connect the front and back and allow the oil to continue unimpeded? What do y'all think about a possible cooler replacement? Something that would possibly be an improvement and more than likely a little easier to seal any leaks if they arise

http://www.ebay.com/itm/30-rows-10A...Parts_Accessories&hash=item3f3018abc1&vxp=mtr

30 row oil cooler with electric fan. I saw one on a D250 similar to this mounted back under the bed between the frame rails, it worked quite well until it's shoddy instillation made it meet highway 80 heh

I have a second oil cooler as a gift from the previous owner of my rig, I might make a copy of it's mount on the CNC and see what can be done about adapting it to an aux cooler.

Another question remains about the coolant that goes through the cooler, would those ports need to be blocked off or should I connect the front and back and allow the oil to continue unimpeded? What do y'all think about a possible cooler replacement? Something that would possibly be an improvement and more than likely a little easier to seal any leaks if they arise