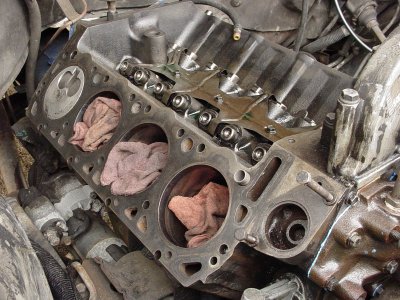

well today i was able to finish tearing the motor down all the way, every thing looked good. i could tell that someone had already been in it, by the permatex that was on the head gasket. how stupid can you be im surprised that the head gaskets lasted as long as iv owned the truck. i tell you ive been patching this thing up since i bought it, i couldnt believe that someone could do so much damage to a truck, needless to say something so stupid. i have a question about something, why do you have to replace the head bolts when you do a top end job, cant you just clean them up real good and run a die on them to refresh the threads. ive rebuilt alot of chevy engines and you could reuse the head bolts. whats so different about these engines. i realized today what everybody was talking about having a shop crain to put the heads back on with, man these things are beasts. i know there no small block chevy head. lol.

i have to do another one i will pull the motor!!!

i have to do another one i will pull the motor!!!