So it comes to mind a lil something that I wonder about.

Now let me go back to my temder young teenage years first...my 1969 Ford Cortina GT.

I worked in a speed shop and built a wicked engine...this engine had piston jets in the rods...there were small holes in rods a d bearings correspondingly that when the rod passed the oil journal in the crank a spit of oil woukd shoot up in the cylinder....timed by location of oil journal hole in crank.

I dont think it was a constant stream but maybe ....

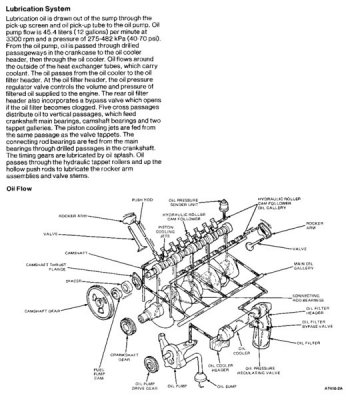

Now come to our IDI engines with piston cooling oil squirters....how do they function?

2 hypothesis I have...

1 It is a constant flow of oil sprayed up into cylinder and bottom of crown of pistons.....means lots of oil spraying all over in there.

2 Timed spray pattern...how?...well as the engine rotates the valves actuate lifters which have an oil jornal feeding them ..up down they go...cover uncover a port to squirters....but I honestly do not know....

So to all ya older timers with IDI knowledge...which one is it?

I wanna know...and Enquiring minds wanna know eh?

Now let me go back to my temder young teenage years first...my 1969 Ford Cortina GT.

I worked in a speed shop and built a wicked engine...this engine had piston jets in the rods...there were small holes in rods a d bearings correspondingly that when the rod passed the oil journal in the crank a spit of oil woukd shoot up in the cylinder....timed by location of oil journal hole in crank.

I dont think it was a constant stream but maybe ....

Now come to our IDI engines with piston cooling oil squirters....how do they function?

2 hypothesis I have...

1 It is a constant flow of oil sprayed up into cylinder and bottom of crown of pistons.....means lots of oil spraying all over in there.

2 Timed spray pattern...how?...well as the engine rotates the valves actuate lifters which have an oil jornal feeding them ..up down they go...cover uncover a port to squirters....but I honestly do not know....

So to all ya older timers with IDI knowledge...which one is it?

I wanna know...and Enquiring minds wanna know eh?