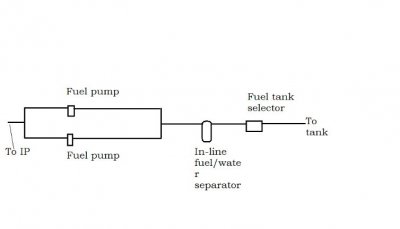

I need help to understand how pumps work. I have a fuel volume problem I believe with My actual pump and I do not want to spend money on another pump so I thought about installing two pumps (both rated 10psi) on the same fuel line. Is there a problem with this? What happen if one pump eventually dies, will the other one still be able to pump through the dead one until I get somewhere I can replace the dead one? Or should I put a separate line for each pump so both pump fuel into the same fuel line?

Right now My fuel pressure is good but as soon as I put My foot in it the pressure goes down fast and the pump I have right now can take 15psi all day so I'd like to supply more fuel to it.

Any help is appreciated.

Right now My fuel pressure is good but as soon as I put My foot in it the pressure goes down fast and the pump I have right now can take 15psi all day so I'd like to supply more fuel to it.

Any help is appreciated.