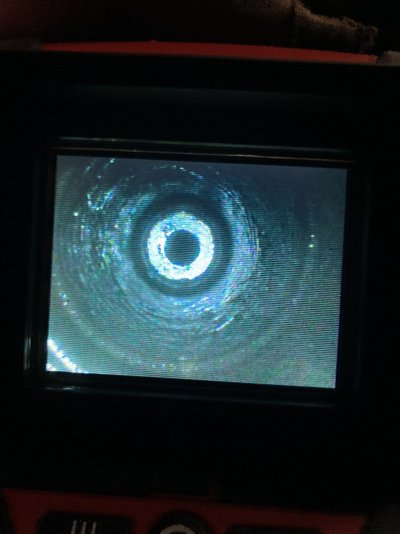

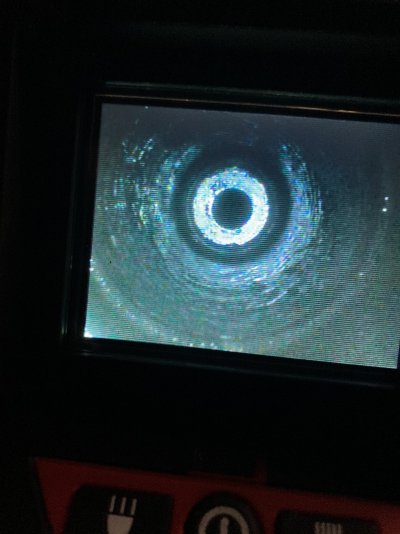

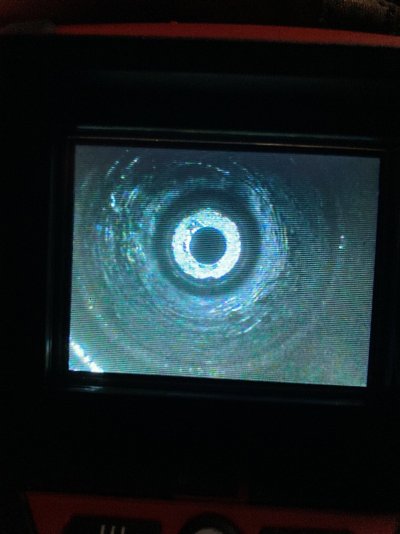

So... Number 7 cylinder had bubbles coming out around the injector, and no matter what I tried I just couldn’t get the return line fitting to stop leaking. I thought it was a bad copper seat/seal so I pulled the injector and it was UGLY. These were “new” injectors from rockauto about 5000 miles or so ago and you guys know I threw moose Junior and a factory turbo with all the flow upgrades at this thing and a whole new fuel system and I’ve had nothing but grey smoke issues. I was tinkering with timing and got it to idle pretty nice and the smoke went to pure black (yay!) so I figured what the hell let’s pull #7 and see what’s up. The injector was completely covered with crusty tar-like layer of goo. I put a magnet to it and there may be some steel dust in there from what I can tell. I’m going to worm a bore scope down there tomorrow to see if there is visible piston damage, if not then do a compression test. I have the numbers from a test prior to my “upgrades” so it should be pretty obvious if there’s an issue but does this even look close to normal/expected? If I had to guess that cylinder was NOT firing and this is all the gunk from blow by and no combustion ... and the spewing fuel around the return line connector was because no fuel was making it through the injectors nozzle and it was pressurized at the return port ... makes sense? more to come.....

You must be registered for see images attach

You must be registered for see images attach