@Big Bart, @IDIBRONCO, @The_Josh_Bear & others et al...

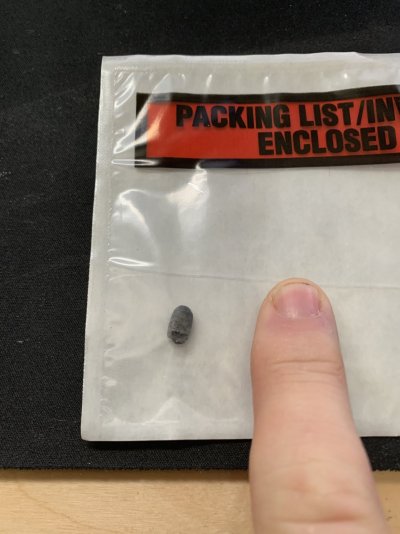

First, can't be grateful enough for everyone's thoughtful and good advice. I've spent the last few weeks trying to find and remove the 3/8 inch tip which broke off and dropped right in. I've learned a lot about what can and cannot be done *after* the GP tip has dropped into the cup, and much more likely - into the cylinder itself.

If you are a newbie to this space and broke one off I'll get right to the point - you will NOT get the damded thing out, and unless the engine cost/benefit is negative - stop right now and pull the heads. Either yourself - or pay to get it done. The practical "this might work" of all shopvac methods - is highly unlikely. If your endoscope can't see the tip INSIDE the cup - just stop. Worse than that - you're more likely to push the tip into the cylinder than to retrieve it (someone find me 4mm grabbers...).

Of all the non-destructive methods to extract broken off GP tips, the two I have not tried: 1) rotate the piston to open the exhaust valve - then "shop vac". 2) Just run the damned engine. Since I have spent a good deal of time with magnets and 4mm/5.5mm endoscopes... and have YET to see the GP tip - I conclude it fell right through the cup onto the top of the TDC piston in #2. I do not have the tools to force the exhaust valve open and blow/suck/force anything out of the cyl, and I don't really want to rotate and force the tip into whatever.

Since the compression numbers were really good, the engine is highly likely to be worth saving, it might even be a fresh rebuild. Which excludes the "just run it" methodology. It is entirely possible the shopvac methods worked, but with a detail inspection of the shop vac paper filter not coming up with any metal (none) and the compression numbers being good, we're just not going the "crank it and pray" method - which had some merit given the costs involved... $5K for a rebuild, or $2K plus-plus to yank the heads for a 50/50 bet.

So, the outcome of this little ****** Glow Plug experience, is it will go to the local Diesel Performance shop - it is out of my hands. As an engineer or consultant of any kind - the key to success is to know your limits, both of knowledge and of risk. This one is past me. The truck may have $8K in parts already, only be worth $5K as I write this (keeping it ugly... !!!)... blah blah blah.

The only things left to decide are what shop CAN/Should do the work - and what other things should be done while in there... This is what I'm likely to do... "since I'm in there"...

Obviously: Install ARP Head Studs - you have the heads off, just DO this. Machine the Surfaces, Cleanup Everything, valley pan blah blah blah... every gasket/consumable etc.

But realistically - I'm likely to also:

1) Rebuild the rest of the heads. Valve, seats, springs, guides...

2) get the Turbo work done with a new Standyne & Injectors

I'm going to accept that I put a bad GP in #2. And that I just have to go forward.

Again - thank you everyone. Lets close this thread out...

First, can't be grateful enough for everyone's thoughtful and good advice. I've spent the last few weeks trying to find and remove the 3/8 inch tip which broke off and dropped right in. I've learned a lot about what can and cannot be done *after* the GP tip has dropped into the cup, and much more likely - into the cylinder itself.

If you are a newbie to this space and broke one off I'll get right to the point - you will NOT get the damded thing out, and unless the engine cost/benefit is negative - stop right now and pull the heads. Either yourself - or pay to get it done. The practical "this might work" of all shopvac methods - is highly unlikely. If your endoscope can't see the tip INSIDE the cup - just stop. Worse than that - you're more likely to push the tip into the cylinder than to retrieve it (someone find me 4mm grabbers...).

Of all the non-destructive methods to extract broken off GP tips, the two I have not tried: 1) rotate the piston to open the exhaust valve - then "shop vac". 2) Just run the damned engine. Since I have spent a good deal of time with magnets and 4mm/5.5mm endoscopes... and have YET to see the GP tip - I conclude it fell right through the cup onto the top of the TDC piston in #2. I do not have the tools to force the exhaust valve open and blow/suck/force anything out of the cyl, and I don't really want to rotate and force the tip into whatever.

Since the compression numbers were really good, the engine is highly likely to be worth saving, it might even be a fresh rebuild. Which excludes the "just run it" methodology. It is entirely possible the shopvac methods worked, but with a detail inspection of the shop vac paper filter not coming up with any metal (none) and the compression numbers being good, we're just not going the "crank it and pray" method - which had some merit given the costs involved... $5K for a rebuild, or $2K plus-plus to yank the heads for a 50/50 bet.

So, the outcome of this little ****** Glow Plug experience, is it will go to the local Diesel Performance shop - it is out of my hands. As an engineer or consultant of any kind - the key to success is to know your limits, both of knowledge and of risk. This one is past me. The truck may have $8K in parts already, only be worth $5K as I write this (keeping it ugly... !!!)... blah blah blah.

The only things left to decide are what shop CAN/Should do the work - and what other things should be done while in there... This is what I'm likely to do... "since I'm in there"...

Obviously: Install ARP Head Studs - you have the heads off, just DO this. Machine the Surfaces, Cleanup Everything, valley pan blah blah blah... every gasket/consumable etc.

But realistically - I'm likely to also:

1) Rebuild the rest of the heads. Valve, seats, springs, guides...

2) get the Turbo work done with a new Standyne & Injectors

I'm going to accept that I put a bad GP in #2. And that I just have to go forward.

Again - thank you everyone. Lets close this thread out...