MTKirk

Full Access Member

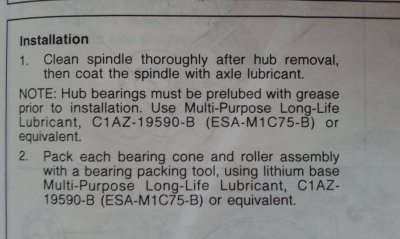

The manual is pretty adamant about greasing the bearings, note the word "MUST".

I've installed a few of these with no failures thus far http://www.amazon.com/Timken-370047A-Oil-Bath-Seal/dp/B001542MN8 They are 2 piece type that comes with it's own installer. Whatever type of seal you get; Make dang sure your vent is functioning properly, excess pressure is what makes most seal leaks start.

I've installed a few of these with no failures thus far http://www.amazon.com/Timken-370047A-Oil-Bath-Seal/dp/B001542MN8 They are 2 piece type that comes with it's own installer. Whatever type of seal you get; Make dang sure your vent is functioning properly, excess pressure is what makes most seal leaks start.

Attachments

Last edited: