You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Performance Cams for IDI, Not a Regrind. Interest??

- Thread starter DragRag

- Start date

icanfixall

Official GMM hand model

A stock cam has the same lift on both intake and exhaust. As for valve to piston clearance what you can do is install a set of Mahle low compression pistons and mill no more than 15 thousands off the tops. That right there will gain you 25 thousands more piston to vavle clearance on a stock lift motor.... Now you can grind for 25 thousands more lift... I don't have the stock piston to valve clearance .... Sorry....

I don't have the stock piston to valve clearance .... Sorry....

I don't have the stock piston to valve clearance .... Sorry....

I don't have the stock piston to valve clearance .... Sorry....I don't have the stock piston to valve clearance .... Sorry....

now that's where plasterscene comes in that clay like stuff we played with as kids just lay a thin layer on the piston top and turn over the engine a few times and them measure it's thickness.....kinda like plasti gauge for piston to valve clearance!

racer30

Full Access Member

performance cam

ok I started with a cam that would fit in a stock engine for engine clearance. the most important thing to remember is this engine has been designed for na application it was turbo charged by the market pressure from the other mfg engine's it was then redesigned as a turbo charged DI engine. when I started to push this stock engine on the program it made big numbers but went to verry high pressure and temp. when I lower the compression and increase boost the engine responded with better performance with less heat and pressure. when you change compression you get more room for the valves even though the best performance didn't need that much lift added to the cam. I ran several grinds that put the engine into the higher rpm range but remember it costs alot of money to lighten the rotating mass to use it. sorry to say but I put together alot of this info over on DB site under aftermarket- custom cam grind. I planed on doing a thread here to.

ok I started with a cam that would fit in a stock engine for engine clearance. the most important thing to remember is this engine has been designed for na application it was turbo charged by the market pressure from the other mfg engine's it was then redesigned as a turbo charged DI engine. when I started to push this stock engine on the program it made big numbers but went to verry high pressure and temp. when I lower the compression and increase boost the engine responded with better performance with less heat and pressure. when you change compression you get more room for the valves even though the best performance didn't need that much lift added to the cam. I ran several grinds that put the engine into the higher rpm range but remember it costs alot of money to lighten the rotating mass to use it. sorry to say but I put together alot of this info over on DB site under aftermarket- custom cam grind. I planed on doing a thread here to.

88 Ford

Full Access Member

I like how the Type4 builds horsepower and torque down low. I know it was built for a n/a engine but I'm sure there's a pretty good performance gain with a turbo also. Idk maybe you might be able to squeeze a little more with a grind for a turbo engine but the only real way to know would be to dyno the Type4 cam and whatever grind you come up with in the same engine. That will show the real gains.

racer30

Full Access Member

I ran a base line engine on the computer ajusting head flow and piston friction numbers from the programs questions about the short block bearing size and other info about the fuel ratio, rpm range ect. until I was happy with the numbers the dyno put out for a stock engine. then changed one thing at a time to see the improvement in performance the dyno seems to be verry generous because there is no mechanical injection option to use on the program. the trends in the info is what is most important. this program shows changes in dynamic compression, boost compression, effective stroke, cylinder pressure, exhaust temp at the valve, vollumetric efficiency, machanical efficiency and many more bits of info. I am better with a stearing wheel than a keyboard so it will take some time to work through this info and make graphs to show the data.

racer30

Full Access Member

I need to fix the mother inlaws car today and get a load of fire wood so I will be back on this evening to put up more info.

88 Ford

Full Access Member

Damn that programs seems pretty cool. Where did u get it?

racer30

Full Access Member

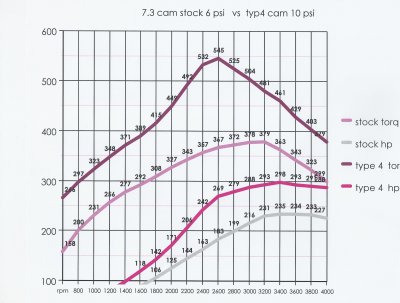

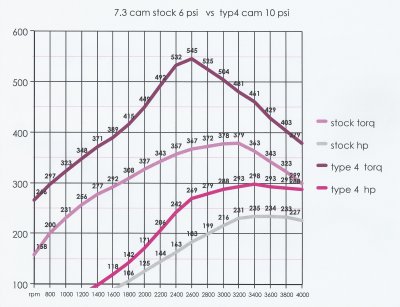

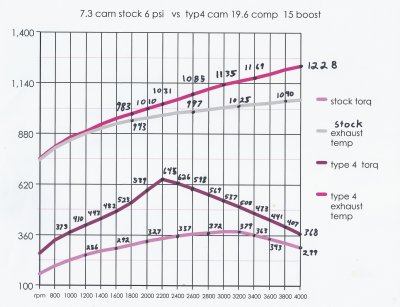

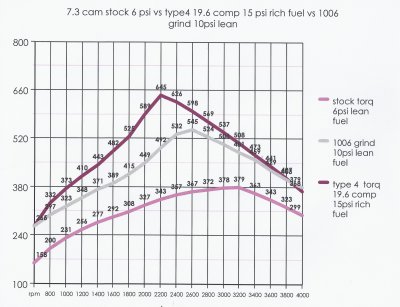

The program is called performance trends 3.9 its verry expensive but they have a demo version you can download for ten days you can use most of the programs features but it will only let you print a few graphs then it wont let you print anymore. It will let you run and store info to compare to each other from a list of runs. It took me a few nights to get all the engines info that the program wanted like valve size and port length and width I have a disasembled engine that I used for measurments and I surfed the web for other info I used Wallace Racing for engine calculations to try and back up some of my info on the program it has calculators for things like bearing friction and things like that. so I burned up a few days of my ten digging for info, so I had to make notes from the programs screens to make my own graphs on the things I felt were most important to my research on cam performance, Here are some graphs to compare make sure to read the info on the top. oops got one on there twice.

Attachments

Last edited:

any way you can get a readout for a type4 cam with a 19.5 cr and about ~25 lbs of boost? and can you change the temp of the air going in, say intercooled vs non intercooled? i dont know how that programs works, just wonder if its possible

racer30

Full Access Member

cylinder head flow has a effect on torq and hp but not quite the way you might think. when I increased head flow on the intake side the torq numbers moved up the rpm range. if I raised the boost it would move back down again. but would peak at a higher rpm. If I raised exhaust flow the turbo would spool faster and torq came on sooner. The flow rate on the intake is less important than the pressure. lobe lift has a similar result. adding lift to the cam made bigger numbers in the higher rpm range. adding duration to the cam made everything move up the rpm range to but dropped boost at the low end. I think there are gains to be made from mild port work on the intake side, but dont make the port bigger just remove obstructions and port matching. The exhaust side needs the same work with special attention to keeping the size of the port and the manifold from changing size so the gasses dont expand until the turbo. "This info came from a article in diesel truck mag" . I put that info into the dyno and it made 8% increase in torq and 6%hp. on the stock engine, and 11% and 9% on the type4. Now when you look at piston design you find the IDI has a dimple and two round depressions for dispersing the flame from the pre chamber. The di engines can use a recessed dome piston so the fuel/flame can move out from the center. I want to do some research on piston design to find the best way to lower static compression and get good fuel/flame movement into the cylinder head at the same time.

racer30

Full Access Member

yes the program has a intercooler and yes it makes more power and lowers the egt there are alot of variables in the intercooler applications. I did run some runs with a typical intercooler and it would take 90 to 125 degrees off the egt depending on the fuel load. and a increase of 30 to 70 torq the ambient temp is what makes alot of the difference. the program dosent give a air in to engine temp and the exhaust temp is at the valve. I ran some wild combos just for fun but I dont think they are really important to the goal of improvement in engine performance.

Last edited:

racer30

Full Access Member

The #1006 grind is the grind that Ken from Oregon cam recommended it makes good power but it is later in the rpm range, I think this would be a good grind for a truck application but I really like the low end of the type4 cam. here are the cam specs. stock intake 102.8 centerline 240 duration valve opens 17.2 btdc close 42.8 abdc lift .2535 exhaust 105.2 centerline 252 duration valve opens 51.2 atdc close 20.8 bbdc lift .23508 lob sep 104 overlap 38 TYPE4 centerline 102.0 duration 187.5 opens 7.8 btdc close 15.3 abdc lift .261 exhaust centerline 105.1 duration 198.6 opens 23.9 atdc close 5.4 abdc lift .253 lob sep 103.5 -13 overlap #1006 grind intake centerline 108 duration 203 valve opens 6.5 btdc close 29.5 abdc lift .273 exhaust centerline 112 duration 208 valve opens 36 atdc close 8 abdc lift .283 lobe sep 110 -14.5 overlap the #1006 has just little more lift and duration than the TYPE4 cam thats what makes it peak at a higher rpm. if you compare the numbers you can see the stock cam just opens the valves to soon and holds them open to long to make good use of the boost we try to put in the engine. when you change the cam it changes the personality of the engine. the stock cam is a nerd and the type4 is a body builder.

racer30

Full Access Member

the cam is every thing to the engine without the correct grind it holds back the performance. just like the engines I built for my race car its all about the little things. when you add up all the things you do to make the engine run at peek power it will come together as a package.