OP you can skip down to the bolded part if you dont feel like a heavy reading, its labelled "Supercharger part" and has my couple inputs. Sorry for the length, only read if bored I probably made an ass of myself..

Whats the maximum cc's we can hog a db2 out to, extensive modifications et al? I've seen a claim or two for a bit past 120 but IDK how or if it was even a db2 by the end. I've heard db4 plungers can make 150cc?

We can build the pressure, 6.9s with stud kit can handle the boost... but with 90cc's from a moose/120cc sm theres NO way we can get 300+rwhp with just #2 fuel and air.... Can the cooling system handle increased heat? The radiator I've got is the size of a boat.. But I've never had a chance to load it real heavy only a few tons. Theres always ****/water misting to cool her down

Everything said below is NOT tailored to N/A setups... because honestly you wont have much power N/A (no offense intended n/a guys but forced induction and diesel are a match made in heaven for performance

. Only mentioning this to cover my bases)

High powered idis been' done before, its rare and costly but not impossible. Just too high above what most are willing or capable to spend and risk

-------------------------

Gonna toss out some ideas I've been mulling on for some time. I am probably off on a bit of points here but figured I'd say something and figure out what might be a good or bad idea

For more power, we need more fuel. DB2 limits, alternatives?

For the engine I'd go a 6.9 bored out some, for instance 60 overbored (4.06 bore, while 7.3L stock bore being 4.11 or 58.82% difference between the two for protection against cavi) and a stroke job around 1/8" will have a little over 7.3L displacement without the risk of cavitation like on the 7.3 IDI. Thats just covering the bare displacement... Then theres the fun on pistons & rods

Ceramic coat pistons, heads, blah blah blah. Coating only adds 0.0003 to 0.001 inch from what I've looked into... Teflon coating ought make things move a bit smoother too. Port & polish, open 'em heads up. studs of course... Cam grind. Balance the assembly to be safer at higher rpms, straightening if needed

, etc. shorty or medium headers, either tri-y or 4-1 to the turbo... coat em too

Supercharger part \/

The new variable vane turbos coming out like the holsett hx35 reduce the problem of turbo lag and make supers more obsolete... supercharger + diesels low rpms are a bad combo unless you change the pulley to something smaller, this would increase the workload though but boost as well by increasing rotations at the super... Just something worth noting.

Turbos are nice in that they work up to match the load, as exhaust gases get hotter and thusly move at a higher velocity from the block,the turbo will speed up and feed even more o2 for combustion with its own RPMs independant of the engine, a super just looks at the RPMs and is limited thusly... A low rpm range combined with a super on a mechanical injected IDI sounds a bit barbaric

. You'd want to governor to 4k at least with a super. But it definitely looks awesome!

would be custom exhaust from headers to exhaust tip but a hx35 mounted to an IDI with upped fuel amounts, proper up & down pipes, intercooled, studded everywhere, opened heads, prechamber hole opened some, etc... ought be pretty beefy combined with a nice filter like the 6637 covered with ram air. You'd have almost no restriction when not moving, and when moving positive air pressure

before the turbo lightening up the work it has to do.

Supercharger part /\

Supercharger part /\

Most people I've seen or talked to forget a sem-important thing when routing intake and exhaust... The more bends and the harsher the bend angles, the more air restriction is created. Routing is more critical on fluids but it can have effects on airflow too. When planning an intake or exhaust you want it to be as straight as possible, when a turn is needed try to give it a large gentle bend(s) rather than a hard 90° turn or sharper, the gases slam into the ends and its as negatively effective as adding on extra piping.

. Can't remember what its called other than proper routing... its 8am and I've had no sleep so sorry but the easiest way to demonstrate the idea is to think of the difference between a 45° bend and a straight pipe... harsh contrast. A pair of 135°'ers can get you in the same place as a 90. sometimes harsh bends are needed but just thought I'd throw it out

As for injectors, I think the cummins injectors nozzles shoot out multiple points (whereas ours are straight out the tip) = more atomizing : commonrail injector as example:

http://www.youtube.com/watch?v=g6q8d22RhGc see how that baby mists

. I've read some modifying the injectors, we could probably use the nozzle from them multiple output injectors attached on our injector bodies,i think i've heard of hogging the insides out to hold more fuel or something along them lines, then theres pop pressure shimming, etc. With the head dissected in Mels photo, it looks like very careful machining could move the injector forward through the prechamber a short length to get a multiport nozzle inside while being thinner material,not sure how much material a injector reamer can eat through but if they are any decent it would be nice of someone to try on a junk head. combine that with a multi-port nozzle and it'd fumigate/atomize real nice or one could just open the nozzle hole up a tiny bit. I havent thought it through fully I figure some other brains can give it a whirl lol

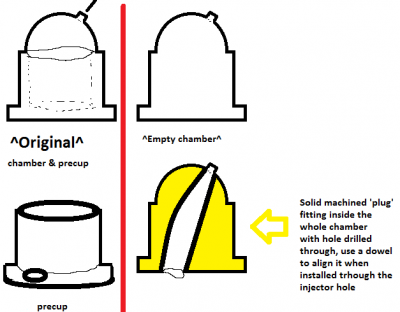

As for making the engine DI from IDI, I've mulled it over a bit. The Precup can be pulled out, and a simple plug/funnel thing could be machined made from round bar stock and inserted with a dowel to help align it during installation. I'll upload a bad pic I just made in paint to help convey the image somewhat, see below

http://www.oilburners.net/forums/attachment.php?attachmentid=33965&stc=1&d=1298307825. The tunnel could be more conular with the small end at the injector, and other tweaks but its a good enough napkin drawing to get a thought out. Only problems I could guesstimate would be the engine dynamic would be different (obviously), machining time/effort/costs to make the plug/funnel-doohickey-probably use aluminum round bar or something preferably higher temp capable

. The only other problem I would see with an insert like that would be puddling/collecting of the atomized fuel - but honestly 2k PSI fluid is flowing so fast that it might not be a real problem esp. when considering the gains -DI combustion process is quite a bit faster than IDI combustion/precomb, esp. considering all of that reaction has to start in a soiled deoxygenated precup and burst forth from a small opening

. Might be possible to cut in a groove for firerings in the theoretical chamber plug as well

. Not sure how well that'd seal up to be honest but would be cool if it did work

. if only I had heads to sacrifice and skills needed. Either way the compression would be increased by filling the chamber, it could then be lowered some with some nice aftermarket pistons..

I think the major hinderances are that its not easy as in buy it off the shelf toss it in et voila powerhouse. And that we've all gotten use to accepting the motors for what they were and using them for workhorses. I'm sure with some modification a streetable, workable IDI could be had - maybe not modified as hefty as I mentioned above but thats what experimentation is for. Dyoung boosting 28 psi and only blowing a HG running reused head bolts iirc

. Stroking shows better benefits than boring when the cubes are equalled... I've seen people bore, but I have yet to see anyone stroke an idi on OB unless I've missed you accidentally.

. Don't need a new crank, can get them grind 'n filled, is it viable?

Usually all I hear is: performance pump, intercooler,turbo, 3" downpipe, 4" exhaust, intake, propane/****/water (rare), then a 'all you'll get is 200hp or thats all these can do [without extensive mods]'. That photo of the white truck has an IDI that did 9 something seconds, so it isn't

impossible but lately it seems to be treated that way. Haven't the 6.2s been hopped up a bit, where did they succeed that we are failing besides $

http://www.dieselpowermag.com/tech/...esel_engine_power_recipes/water_methanol.html is it the price tag alone? All I see in this article is inject nat. gas, propane, **** and $$$ for 300-500hp for the 6.2... Much easier to buy a cummins, turn the pump up and toss it in the ole ford I guess I can't blame people for doing that. I just don't think there should be a 200hp wall that cannot be exceeded without dropping exponentially more $$

I know someone in the world somehow mated a 8-cylinder-p-pump to an idi, that oughta do the trick on fuel if the db2 couldnt with the prechamber opened some more and more boost.... POWER? I know I know... price

Time to get a couple hrs sleep. Sorry for the book, I'm no pro I probably sound like an idiot and probably am ramblin since its 9am with no sleep. Plenty of people asking about power lately thought I'd chime in. Oh well

When the torque drops instead of staying flat, that usually means you are running out of fuel or air.

. You'd want to governor to 4k at least with a super. But it definitely looks awesome!

. You'd want to governor to 4k at least with a super. But it definitely looks awesome! . Stroking shows better benefits than boring when the cubes are equalled... I've seen people bore, but I have yet to see anyone stroke an idi on OB unless I've missed you accidentally.

. Stroking shows better benefits than boring when the cubes are equalled... I've seen people bore, but I have yet to see anyone stroke an idi on OB unless I've missed you accidentally.