Check the converter drain, "snug" fit can loosen itself easy depending on how tight (or loose) it actually is. Also, the pump has some sort of o-ring or gasket sealing it to the case, right? Any chance that got damaged somehow? Also you did make sure the converter was seated all the way in before you reinstalled the transmission?

Pull the shield plate with the tube and take a look in there, maybe you can see where fluid is coming from. If converter is leaking the whole bell will be sprayed with fluid, if it's something pump related likely only the bottom part of the bell will be oily.

yeah,i will double check it but as fast as it's pouring out,im afraid the plug would have to be pulled right out to leak this much.however,simple things first for sure.

yeah the pump has a gasket on the back side.i carefully removed and re-used it.

there is also an o-ring going around the whole outer side of the pump which was also in tip top shape.

yes.back as a teen,my old man warned me about pump damage and to insure the converter fully seats.

it's fairly obvious when a converter isn't fully seated though,as she just doesn't set in far enough like when she's seated.just the same,i always fully seat them and then turn another 5-6 full turns just to make sure of things as just doesn't take long.a little overkill but iv always done it.

i figured i'll try pulling the shield too but i doubt i'll be able to see anything helpful.but free and easiest things first for sure.

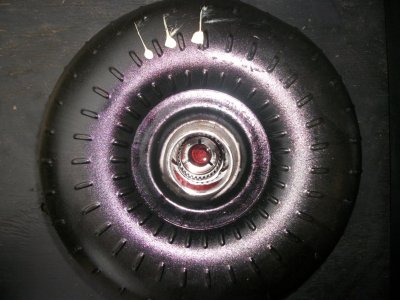

Could be a bad pump bushing. A new seal will not stop a damaged or worn bushing from leaking.

Check the converter hub too. Any damage or wear will make your new seal leak.

i did check out the inner bushing in the pump,though kinda hard to see it very well,it "appeared" fine with the grooves very distinct and deep looking.so as it appeared not to be worn down to the grooves at all.but i dunno.iv never had one fail on me before.always lucky with those perhaps?

iv never had a bell housing leak like this,that a front pump/converter seal didn't fix.

i wish i inspected the converter hub better.i don't recall anything out of the ordinary with it right off,but i may have taken a pic of it.i'll check...................dang i guess i didn't.i remember thinking about it but didn't.perhaps that would have come in handy.son of a gun.

well i guess i'll probably just have to pull her out again this weekend and try again.if i can't find the issue i'll post pics up and if that's not enough i'll haul the old gal into the trans shop and see if they see the issue with they're trained eyes.

thanks guys! we'll find the issue this time hopefully.i'll take pics of anything and everything and post 'em up.