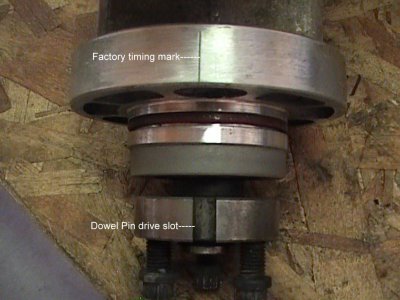

Pull the IP solenoid cover off, it should be full of diesel. Hook up your 12V to the solenoid, make sure it is working. You can pull back the shut off slide by hand, spring should close it when you let go. About the only way to see if the input (IP drive shaft) is broke, take the front cover off the gear tower, turn the engine over by hand until the drive dowel is at 12 O'clock, clean and remove the cover on the side of the IP, stick a 5/32" hex key in, like adjusting the fuel, then see if you can move it up and down, should be NO movement, if so the shaft is broke. The last pic shows the drive shaft broken, this was the results of turning up the fuel and the screw head broke off. Not mine.

Just make sure when you put the solenoid cap back on, it's in the right position, see pic.

Just make sure when you put the solenoid cap back on, it's in the right position, see pic.