Thefarmboy21

Full Access Member

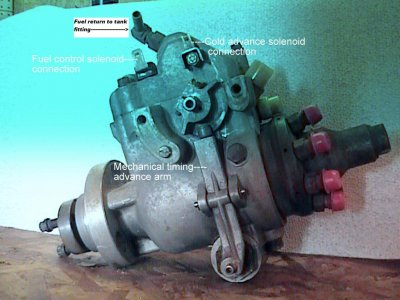

Alright fellas, I have an 87 F-250 with a 6.9 and it has the new style glow plugs etc... I just put an older motor in the truck to replace the one that slung a rod. My problem is that the injector pump won't send fuel to the injectors. I used a vac pump to get fuel up to the fuel pump, then did the bicycle valve in the filter head and I opened the two 1/2" bolts on both sides of the IP and they both pushed out air then fuel. No matter how much I crank the IP won't pump fuel to the lines and injectors. I havent checked to see if the IP has power to the fuel shut off but the cold start solenoid has power because it flips my throttle back every time I hit the key so I figured the IP probably had power. Also I disconnected the white wire from the GP controller so I didn't burn them up. I ran my batteries dead twice trying to get fuel pumped up and got nothing. I know my first step is check the IP for power but after that I'm stumped. The truck would start up before I changed the motor but had two holes in the oil pan lol. The new motor is an older motor (Blue with old glow plugs) and all I did was change GP's and wiring harness and drop it in. Never heard it run tho. Any ideas??? Anything you've got would be greatly appreciated. I'm fairly new to the IDI world but I'm no stranger to the garage or toolbox an I've done a lot of IDI homework while doing the motor swap. Thanks guys!