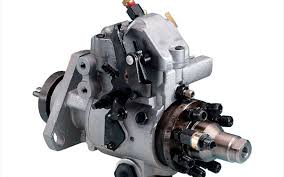

Hmm... sorry to see this is still an issue for you. I remember when you first called about it, and then we spoke again and you said it was solved, and the problem was with the meter? Anyway, the thing is this, and I'm not in any way saying your not seeing what your seeing, BUT.... it is physically impossible for proper rotation of the pump to result in a timing result that is the opposite of what physics dictate must be true. Look at it this way, when the throttle is in the full throttle position, you have zero degrees of advance. The cam ring is now engaging the plungers as late as possible. The engine is turning the plungers against the cam in a clockwise fashion. When you rotate the pump counter-clockwise, towards the passenger fender, you are rotating the cam ring INTO the oncoming plungers, causing them to collide with the cam ring lobes EARLIER. This results in an injection event that occurs sooner, rather than later. Even if the pump were bad... no advance, or advance malfunctioning, there is no way that earlier timing could not result. It simply isn't physically possible, even stretching the realm of all possibilities that I could possibly think of, I cannot by any stretch of the imagination, come up with a viable explanation for how this could result in retarded timing. I'm truly baffled! I personally built this pump and can vouch for it being 100% when it left. Just to qualm the concerns that this is a GM pump, the main difference internally between a GM and Ford Moose pump, is that the cam ring gets flipped over from one version to the other. If that were true then I would not be able to fit the advance jig which bolts to the side of the pump. There is a grove in the cam ring that engages the jig, and it would have been on the wrong side of the pump. That would be a huge red flag, and prevent any further testing of the pump. And no, there is no possibility that a Moose pump can leave here without being calibrated. The tag on the side does not go on until after that has occurred, the pump gets clear coated afterwards, and there is a bunch of paperwork with 3 different people looking at it. Given the difficulty you are having, perhaps the best answer is to try to time it by ear. I don't ever recommend that, but given that something else is going on that we can't seem to put a finger on, maybe that is the best and most effective way to set it. This may be a longshot, but there isn't anything near the bottom of the drivers side of the pump when you are rotating it, is there? Something that could interfere with the movement of the advance lever?