Upon tear down of my 7.3 I discovered that I’ve had exhaust valve to piston contact on one cylinder. So I’m looking into machine shops in my area to rebuild the heads for me including some Comp 910 springs that I purchased for this build. Obviously going to need new pistons now, my plan was to keep the stock bore and buy a new set of pistons at stock size. My question is, should I be concerned about the block or any other pieces that may need machine work, and does anyone know a reliable source for new pistons & rings?

The overall build plan is to swap out the banks sidewinder for a CDD stage 2 kit with intercooler, 110 CC pump, Stage 1 injectors, comp 910 springs, new push rods, and some other little goodies. All parts have been ordered already.

Thanks in advance!

The overall build plan is to swap out the banks sidewinder for a CDD stage 2 kit with intercooler, 110 CC pump, Stage 1 injectors, comp 910 springs, new push rods, and some other little goodies. All parts have been ordered already.

Thanks in advance!

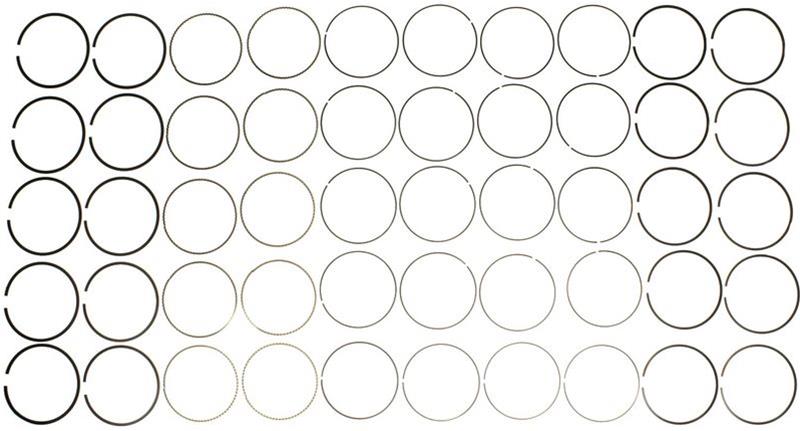

You must be registered for see images attach

You must be registered for see images attach