icanfixall

Official GMM hand model

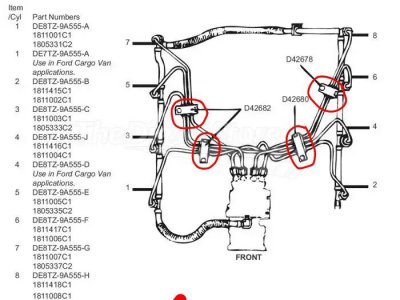

I guess you are home or stranded on the road with more broken lines. Sadly you have learned an expensive lesson as I did many years ago. Those 4 line vibration isolators MUST BE IN PLACE. You and I are living learning proof the hard lines will break. Mine was the number 2 cylinder. Thats the cylinder closest to the radiator on the drivers side of the engine. EVERY cylinder has the number cast into the intake manifold between the 2 bolts that connects the manifold to the head. Just clean off some dirt to see them. You can drive it on 7 cylinders but it will be messy and ruff running. Nothing will fail because of it. Really not very much fuel is actually pumped to the injectors on these engines. Hope you broke and easy to reach hard line. Unfortunately mine was the bottom of the injection pump and I was very new to these engines. A Ford dealer charged me nearly 400 bucks to replace the line. They told me they had to remove every line to reach the broken line...

Later on in my continuing idi education I found out Ford made a special 3/8 drive socket to reach down under the hard lines to remove the 2 impossible to reach bottom lines. BTW they charged me nearly 100 bucks for the hard line...

Later on in my continuing idi education I found out Ford made a special 3/8 drive socket to reach down under the hard lines to remove the 2 impossible to reach bottom lines. BTW they charged me nearly 100 bucks for the hard line...

Later on in my continuing idi education I found out Ford made a special 3/8 drive socket to reach down under the hard lines to remove the 2 impossible to reach bottom lines. BTW they charged me nearly 100 bucks for the hard line...

Later on in my continuing idi education I found out Ford made a special 3/8 drive socket to reach down under the hard lines to remove the 2 impossible to reach bottom lines. BTW they charged me nearly 100 bucks for the hard line...