Okay, bare with me here because this is my first time ever getting this far into an engine and I get confused with over and undersize bearings and all that stuff, haha.

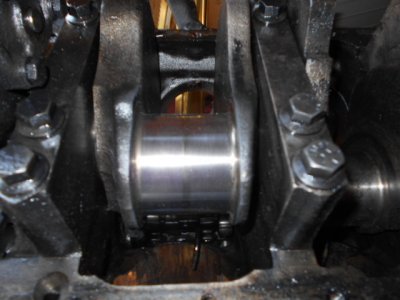

This is my broken crank out of my '91 250.

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

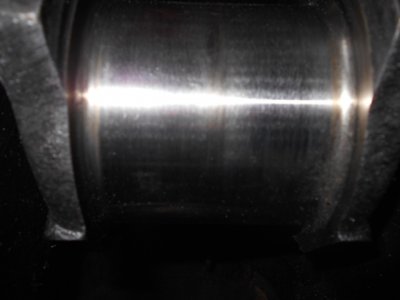

This is the crank that came out of the engine I got to replace mine; '94 250.

You must be registered for see images attach

Now if I am understanding this right.. when I took the crank pictured above to the machine guy to see if he could fix it, he got this little clamp thing out with a digital number display and and it read .070...? That's how much it's been worn down and therefore unsaveable? I haven't gotten it machined or turned or whatever the correct term is for it.

Searching around on the net the "largest" (I'm not sure if I am explaining this part right...) bearing I could find is for .040.