OldIron82

Full Access Member

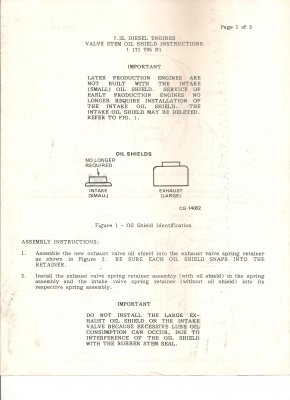

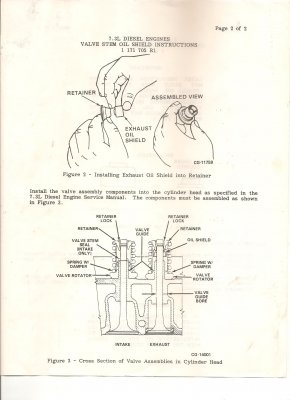

Well, after November being the most interruption prone, inefficient, annoying month of 2015 for me I finally got back to the 6.9. Quick question about valve seals: The old valve seals had a double seal on the intake side. Basically, the small little exhaust seal was under the meaty rubber one, so technically 16 pieces for the intake side. The new kit i have only has the thick meaty rubber seal for the intake side for a total of 8. It's this acceptable? Was this a design upgrade? If I get these valve seals done tomorrow I can finally get the heads back on : )

Ok, two questions. I forgot. Tightening the nuts on the studs. The ARP instructions say due to their super installation lube, no tighten loosen tighten loosen procedure is necessary. Just three equal increments up to 80 ft lbs. What is the general consensus on this? I have searched the forums high and low and I read so many different things I have no idea what to do and am genuinely mentally defeated. Thanks,

OI82

Ok, two questions. I forgot. Tightening the nuts on the studs. The ARP instructions say due to their super installation lube, no tighten loosen tighten loosen procedure is necessary. Just three equal increments up to 80 ft lbs. What is the general consensus on this? I have searched the forums high and low and I read so many different things I have no idea what to do and am genuinely mentally defeated. Thanks,

OI82