TwinForks90F350

Registered User

Hello folks, Chris from Long Island here. Been a lurker for while and have learned a lot so finally got a chance to join.

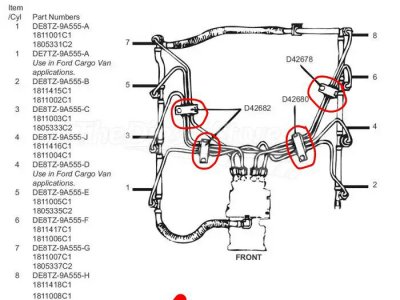

I've seen lots of threads on leaking injectors, bad caps, soft lines, hard lines and o rings and even some mention of worse leaks after a change in the return line kit and now find myself in the position of having a leaky #2 injector, at the top, after several attempts at changing everything. #3 might be developing a slight leak as well ( I've gone over it , and over it and then some, yet the leak seems to get worse. Used Vaseline to lube the o rings, checked the hard lines and cap for cracks, checked and rechecked the threads, clamps and lines. Still leaking. Gonna go over it one more time this afternoon piece by piece and then I'm totally lost. Was trying to avoid another big expense this summer but may find myself at the mercy of the mechanics, ( shop work tends to get real expensive in these parts if you don't really know who is working on your rig ). Anyway, maybe I missed something. Hoping someone might have some info to help before I take it to a shop.

There is also another issue with the new Tranny that I'll start in a new thread once this nightmare is resolved. Seems nobody can figure that one out either and it's been to half a dozen shops, including the re builder. Thanks in advance. Glad to have finally joined. Chris

I've seen lots of threads on leaking injectors, bad caps, soft lines, hard lines and o rings and even some mention of worse leaks after a change in the return line kit and now find myself in the position of having a leaky #2 injector, at the top, after several attempts at changing everything. #3 might be developing a slight leak as well ( I've gone over it , and over it and then some, yet the leak seems to get worse. Used Vaseline to lube the o rings, checked the hard lines and cap for cracks, checked and rechecked the threads, clamps and lines. Still leaking. Gonna go over it one more time this afternoon piece by piece and then I'm totally lost. Was trying to avoid another big expense this summer but may find myself at the mercy of the mechanics, ( shop work tends to get real expensive in these parts if you don't really know who is working on your rig ). Anyway, maybe I missed something. Hoping someone might have some info to help before I take it to a shop.

There is also another issue with the new Tranny that I'll start in a new thread once this nightmare is resolved. Seems nobody can figure that one out either and it's been to half a dozen shops, including the re builder. Thanks in advance. Glad to have finally joined. Chris