Where to start here... how about definitions :

1) No, you are incorrect, it's not "paper" it's a cellulose material that is more accurately called cellulose fiber. There are many products made from cellulose or wood pulp. Certain paints have wood pulp in them: are they "paper?" Chewing gum has cellulose in it... is that "paper?" How about ice cream, which has cellulose ("I'd like two scoops of chocolate paper, please?") Some sponges are made of cellulose and cigarette filters may be mostly cellulose. Cellulose filters have been called "paper" since they first came out in the '50s and when filter media did more closely match the definition of "paper" than it does now. The term has held on since. It's a common colloquialism and I am more or less tilting at windmills trying to change common usage. The only reason I make such a pedantic distinction here is that in the context of these types of discussions, "paper" is used as a disparagement. It's "only" paper! I underwent a "conversion" on this after seeing how cellulose media has evolved over the years, how well it's engineered and so on. There is a LOT of technology that goes into that remarkable product. There are pro and cons to it, of course, but a brand name cellulose air filter packs a lot of value and efficiency into a relatively inexpensive package. I won't argue about the term unless it's used as a disparagement. I am the cellulose air filter Don Quixote, I guess ( : < ).

2) I will caution you not to present advertising materials as "evidence" of much of anything. You know, or should know, that an honest manufacturer is going to put it's best foot forward and present what will be, at best, a biased or incomplete account. At worst, they distort, grossly exaggerate, fabricate results and get sued, as Spectre apparently did. Now K&N is a

great company, with whom I have had many dealings over the years. They have the balls to present all their test data openly, even though some of it is open for critical debate from guys like me. Their engineering lab is second to none. I've been there, I know and I have been in regular contact with their engineers since the '90s. Their products are well built and engineered. They know their stuff! My only criticism is that they have built their foundation on a technology that I think is optimally less suited for an everyday vehicle than a race car. It's debatable, I admit, because the 2-ply K&N filter media does fit into "industry standards" for efficiency, but at the low end of it. If only everything they made was 3-ply and highly efficient... I'd shut up. The efficiency issue is really only a major point in situations where the vehicle is used in a challenging, dusty environment. Personally, given that the air filter is the door to outside contamination getting into my engine, I prefer to have that door opened to the least degree possible. I am willing to sacrifice a few CFM at the upper end in that .5% (optimistically, I am now an old guy) of the time I am at WOT, versus the 99.5% of the time my engine is sucking in dirty air. If I need a performance, high CFM filter, I adapt to as large a high efficiency element as needed (or that fill fit) so I can have MORE clean air. The simple efficiency solution to the OCG efficiency issue is use the foam sock!

3) RE Banks and K&N: I know the very earliest Banks kits used a K&N. By the late '90s and into the 2000s they were not. I asked and was categorically told they were NOT made by K&N but they wouldn't tell me who did. I have no clue who is doing it for them now. In any case, all the OCG filter on Banks kits I have seen, appeared to me to be at the K&N quality level, so Banks likely specs a robust filter from whoever makes them. As OCG filters go, they meet a high standard of quality. In some cases, the available space for a filter dictated an OCG filter to meet airflow needs. The OCG has one of the highest per-inch-of media flow rates out there and if performance is your primary goal, it's one of the best media out there. Just not anywhere near the most efficient at filtering dirt.

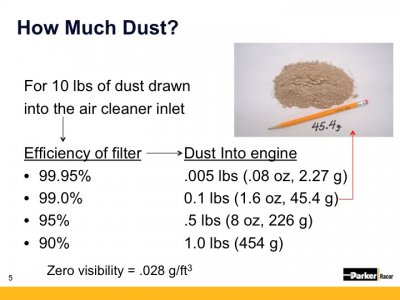

4) Your attachment makes my case. Take note of the initial and final efficiency of 97.35% on COARSE dust. You would drop 3-5% of that on a fine dust test and it is the opinion of many engineers in the field that the fine test is a more accurate and useful test than coarse. They presented a case that put me in their ballpark. The other notable thing in that 1999 test (there are newer test examples out there): take note of how the filtration improves between the initial test and the final. The initial test is a fairly fresh filter. It used to be a perfectly new filter. Now, the latest protocols have a certain amount of test dust applied before the initial reading is taken. That 1999 test is likely the old method. The final efficiency it taken at the filter's maximum restriction, listed at 10" of water. If you go back to that chart I posted, you can see in plain terms how much less dust that change represents. This applies to ANY air filter.

5) ANY restricted filter will pull dirt thru if it's neglected long enough. In fact, the OCG filter is more prone to this than paper and it will happen at a much lower restriction. Does anyone remember the Cummins Tech Bulletin about OCG filters, pull thru on turbo diesel and warranty denials? In any case, the occurrence of pull thru is a maintenance one, not of design. It only happens in extreme cases where a filter is quickly loaded (a Sahara desert dericho, for example) and the operator isn't clued in, or with extreme neglect over time. In any case, the answer is a restriction gauge (just google Filter Minder) that the operator actually looks at once in a while, or frequently as conditions dictate. I knew some guys when I worked for Land Rover who had many African expeditions under their belts. One story I heard was about having to change air filters every 100 miles or so!