ironworker40

NYC Ironworker

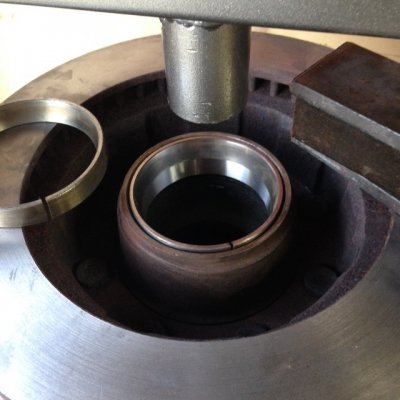

Here is a little trick to help press wheel bearings. I didn't have a driver large enough for the bearing so I used the old races to press new race into hub. If you cut the old races (I used a 4" grinder with a cutoff wheel) this will allow them to collapse slightly so they wont get stuck in hub bore. The pictures are out of order so and I couldn't switch them so vie them from right to left. 1st put new race in bore, then 1 st old race, then second old race. Then I used the square bar on top of stacked races and pressed the new race in. The cut old races come right out.