Wvdirtroad

Full Access Member

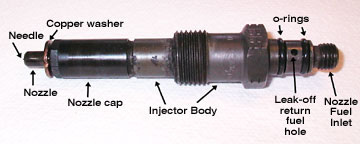

Just received my rebuilt pump from Russ and it includes a pump kit which I didn't expect. I wanted to make sure I'm putting the parts in the right places- did a little searching but not a lot of luck.

1. The kit includes a large Oring, which I assume goes on the end of the pump that slides into the timing gear?

2. There are also 3 olives in the kit- can anyone verify the exact location these should be installed? I believe they are for the return line rail and so forth.

3. There's a smaller Oring as well, but I don't recall removing one from anywhere when I took the pump off.

I appreciate the help. I'm going to start getting this thing back together and see how it runs once I get my new injectors in.

1. The kit includes a large Oring, which I assume goes on the end of the pump that slides into the timing gear?

2. There are also 3 olives in the kit- can anyone verify the exact location these should be installed? I believe they are for the return line rail and so forth.

3. There's a smaller Oring as well, but I don't recall removing one from anywhere when I took the pump off.

I appreciate the help. I'm going to start getting this thing back together and see how it runs once I get my new injectors in.