MJGenay

Full Access Member

I have a '91 F250 7.3 with a ZF5, I'm in the process of installing a Banks Wastegated Turbo Kit on it.

I purchased the kit from Banks. Except for the continuing frustration where I have found over a dozen missing bolts, nuts, and washers thus far in the Banks provided kit (sealed fastener bag) and a incorrectly specified brass plug for the oil pressure sending unit, I have had no other issues until this point. I'm on step 16/17 in the instruction manual.

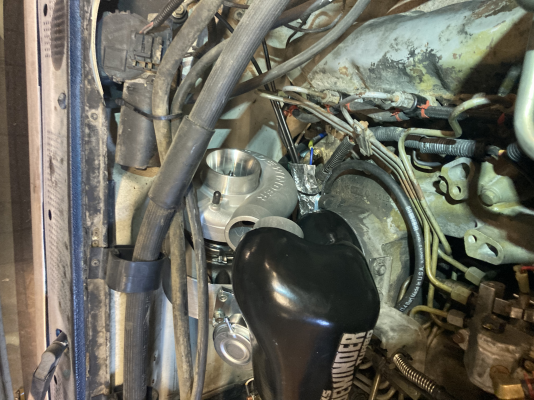

I installed the turbo inlet casting, loosely on the exhaust manifold as instructed in step 16. In step 17 I am instructed to temporarily install the turbo itself on the turbo inlet casting, and install the pressure chamber, so as to line them up properly before proceeding. The output for the turbo and the inlet for the pressure chamber are off by around 2 inches horizontally and a decent amount vertically, in fact I can't even get the pressure chamber to sit on the intake properly as it is bumping into the turbo.

The instructions state to adjust the pressure chamber/turbo alignment by loosening/tightening the nuts on the casting/exhaust manifold. My current conundrum is while I can get the turbo inlet casting onto the exhaust manifold bolts and the nuts/washers on the bolts, the casting doesn't line up perfectly with the manifold bolts (maybe I'm expecting too much but it is a little cockeyed). At any rate, the adjustment available from those two fasteners on the manifold is far from enough to get me the movement required so things line up. The current issue seems to be the "foot" on the turbo inlet casting is preventing me from dropping the casting down far enough to put the turbo in the correct position. This foot sits on the engine to transmission adapter plate. I feel as though if I grind the foot off, both bolts on the exhaust manifold will line up better with the turbo casting and I will be able to line up the turbo/pressure chamber much better.

I'm seriously considering grinding the damn foot off but I am unsure of how necessary the foot is as a support feature. In my mind, the two hefty brackets that support the top of the casting, and the two bolts that connect it to the manifold, should be sufficient.

To be clear I don't know the history of this vehicle. For all I know the ZF5 was a swap or the exhaust manifold is after market. I doubt both, especially the aftermarket exhaust manifold as the entire exhaust system appeared to be stock. While working on the truck I realized the reverse sensor harness that plugs into the transmission was missing from the engine bay back to the transmission, I rewired all of that to get the reverse lights working. The missing harness makes me think that the transmission was possibly swapped, or dropped to be rebuilt.

I'm hoping to get this wrapped up this weekend or by Monday at latest. Short of a phone call to Banks on Monday the only way forward I can see is grinding that foot off the turbo casting. Any opinions on that or any similar experiences with a way forwards?

EDIT: To be clear I read the forum posting regarding the "log truck" in the past couple weeks and again this evening. I am 99.9% sure I have this casting sitting in the correct position. Maybe I am incorrect, in which case I will hide in shame. I will be back out there in the morning to fool around with the positioning of this again.

I purchased the kit from Banks. Except for the continuing frustration where I have found over a dozen missing bolts, nuts, and washers thus far in the Banks provided kit (sealed fastener bag) and a incorrectly specified brass plug for the oil pressure sending unit, I have had no other issues until this point. I'm on step 16/17 in the instruction manual.

I installed the turbo inlet casting, loosely on the exhaust manifold as instructed in step 16. In step 17 I am instructed to temporarily install the turbo itself on the turbo inlet casting, and install the pressure chamber, so as to line them up properly before proceeding. The output for the turbo and the inlet for the pressure chamber are off by around 2 inches horizontally and a decent amount vertically, in fact I can't even get the pressure chamber to sit on the intake properly as it is bumping into the turbo.

The instructions state to adjust the pressure chamber/turbo alignment by loosening/tightening the nuts on the casting/exhaust manifold. My current conundrum is while I can get the turbo inlet casting onto the exhaust manifold bolts and the nuts/washers on the bolts, the casting doesn't line up perfectly with the manifold bolts (maybe I'm expecting too much but it is a little cockeyed). At any rate, the adjustment available from those two fasteners on the manifold is far from enough to get me the movement required so things line up. The current issue seems to be the "foot" on the turbo inlet casting is preventing me from dropping the casting down far enough to put the turbo in the correct position. This foot sits on the engine to transmission adapter plate. I feel as though if I grind the foot off, both bolts on the exhaust manifold will line up better with the turbo casting and I will be able to line up the turbo/pressure chamber much better.

I'm seriously considering grinding the damn foot off but I am unsure of how necessary the foot is as a support feature. In my mind, the two hefty brackets that support the top of the casting, and the two bolts that connect it to the manifold, should be sufficient.

To be clear I don't know the history of this vehicle. For all I know the ZF5 was a swap or the exhaust manifold is after market. I doubt both, especially the aftermarket exhaust manifold as the entire exhaust system appeared to be stock. While working on the truck I realized the reverse sensor harness that plugs into the transmission was missing from the engine bay back to the transmission, I rewired all of that to get the reverse lights working. The missing harness makes me think that the transmission was possibly swapped, or dropped to be rebuilt.

I'm hoping to get this wrapped up this weekend or by Monday at latest. Short of a phone call to Banks on Monday the only way forward I can see is grinding that foot off the turbo casting. Any opinions on that or any similar experiences with a way forwards?

EDIT: To be clear I read the forum posting regarding the "log truck" in the past couple weeks and again this evening. I am 99.9% sure I have this casting sitting in the correct position. Maybe I am incorrect, in which case I will hide in shame. I will be back out there in the morning to fool around with the positioning of this again.

Last edited: