wftree

Registered User

We were towing a 6,000lbs excavator on a 12,000 lbs Bri Mar deck over trailer. The tongue snapped off and dropped the deck onto the road. After looking at the design it is very poor. I am stuck with this pieces of crap and will need to weld significant reinforcements to get it back into service.

I called Bri Mar and they told me to bad

I would stay far away from this manufacturer they make a dangerous product.

The channel that makes up the tongue is butt welded to the main channel running the length of the trailer. No reinforcement of any kind. After we bought the trailer and it was out of warranty we realized the bad design and added 1/2 steel to the tongue. Unfortunately it was not enough. When the trailer snapped the new steel was the only thing keeping the tongue attached

http://community.webshots.com/album/561672812TaBnbq

I called Bri Mar and they told me to bad

I would stay far away from this manufacturer they make a dangerous product.

The channel that makes up the tongue is butt welded to the main channel running the length of the trailer. No reinforcement of any kind. After we bought the trailer and it was out of warranty we realized the bad design and added 1/2 steel to the tongue. Unfortunately it was not enough. When the trailer snapped the new steel was the only thing keeping the tongue attached

http://community.webshots.com/album/561672812TaBnbq

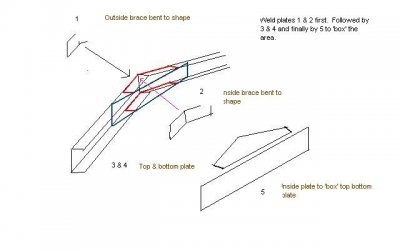

but it conveys what I would do.

but it conveys what I would do.