Hopefully, you got it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Attempting to resurrect an old IDI. HELP PLEASE!

- Thread starter NCTractor6.9

- Start date

Ether and gasoline are both bad ideas, without experience and extreme caution. This cost me an excavator motor. Several people (mechanics) tried to get it started, none successfully. When we did get it started, it had two bent rods, one of which broke after about an hour, spitting the engine almost in half. The original problem had nothing to do with the engine, it was something mechanical dragging it down.

sooooo. this with either or gasoline?????? and you poured a solid stream,,or like I said,,,which makes a M I S T...............and,,ive done this for YEARS. and NO problems!!!!!!!

Bad idea, IMHO. A gasoline-soaked rag would be preferable. Not as much chance of

locking it up. Ether is more controllable. Use it SPARINGLY. The truck will start and

run on ether only, if done properly. Takes a bit of experience.

I suppose the gasoline will work the same, but I would not do it unless it was an

emergency and engine damage was not an issue. The 1-2% oil in the mix is irrelevant.

unless you've done this,, and have had experience with it..me thinks peace is your friend....

ifrythings

Full Access Member

I believe you said you removed the lines off the ip when you removed it, are they back on in the right places and tight? Otherwise I would be bring the engine to TDC and seeing if the rough timing marks line up before you kill the starter, should take no more then 3 rounds to fire one of these up with a new empty fuel filter, ip swap and line bleed, make sure the throttle is wide open while bleeding and a tempting to start.

AcIdBuRn02ZTS

Full Access Member

My truck does the same thing as it stands except I can get it running after a struggle.

Good batteries and cables are a MUST. How cold is it in your area right now? Are you certain the glow plugs are getting hot? My truck currently has dead glowplugs and bad air intrusion. It will sputter and hit on a couple of cylinders. It typically takes cracking all the lines and cranking. Then purging the filter bleed while cranking... Then a shot of ether. It'll hit on a few more. Then a few more... then it'll pick up and finally kick off.

If you have a block heater that works, use it. Pull starting it would be a great option if you can.

A good idea is to get some 1/4" clear tubing and replace some of the injector return lines with it to see exactly what the system is doing and just how much air you are getting.

Slow cranking speed... weak grounds, batteries, air intrusion, cold weather, etc.. all working against you at the moment.

You may consider plumbing in an electric low pressure lift pump to feed the standard mechanical pump. Make sure its low pressure (5psi or so) and let it run for 5-10 minutes and it will purge the air for you without killing the starter or batteries. Then all you'll have to fight is air in the injection lines themselves which is easy enough to purge.

Good batteries and cables are a MUST. How cold is it in your area right now? Are you certain the glow plugs are getting hot? My truck currently has dead glowplugs and bad air intrusion. It will sputter and hit on a couple of cylinders. It typically takes cracking all the lines and cranking. Then purging the filter bleed while cranking... Then a shot of ether. It'll hit on a few more. Then a few more... then it'll pick up and finally kick off.

If you have a block heater that works, use it. Pull starting it would be a great option if you can.

A good idea is to get some 1/4" clear tubing and replace some of the injector return lines with it to see exactly what the system is doing and just how much air you are getting.

Slow cranking speed... weak grounds, batteries, air intrusion, cold weather, etc.. all working against you at the moment.

You may consider plumbing in an electric low pressure lift pump to feed the standard mechanical pump. Make sure its low pressure (5psi or so) and let it run for 5-10 minutes and it will purge the air for you without killing the starter or batteries. Then all you'll have to fight is air in the injection lines themselves which is easy enough to purge.

Last edited:

sooooo. this with either or gasoline?????? and you poured a solid stream,,or like I said,,,which makes a M I S T...............and,,ive done this for YEARS. and NO problems!!!!!!!

I did not mean to question your ability.

You overlooked "without experience and extreme caution". Many people, that are not mechanics, look to these threads for advise.

I don't know how they used gasoline and ether on my engine, I just saw the results. I only know that it was used.

Sorry if I offended you, or anyone else.

fsmyth

Full Access Member

There are Mechanics, and there are "mechanics". Sorta like microsoft "gurus".

My guess - the guys who worked on your equipment were gasoline engine mechanics

with very little, if any, diesel experience. If that is added to a high-hour engine,

sparks usually fly. My sympathies. Good diesel guys are sometimes hard to come by.

IMHO, anyone who uses misted or puddled gasoline in a diesel is living on the edge.

I don't even suggest in my posts that anyone use a gas-soaked rag, although I

routinely do it when ether is not available. Too much room for error.

As always, use only a tiny amount of ether. A 1-sec. squirt is generally ample.

Not that I have anything against gasoline. I mix 15% RUG in my filtered WMO.

Runs great in the IDI.

My guess - the guys who worked on your equipment were gasoline engine mechanics

with very little, if any, diesel experience. If that is added to a high-hour engine,

sparks usually fly. My sympathies. Good diesel guys are sometimes hard to come by.

IMHO, anyone who uses misted or puddled gasoline in a diesel is living on the edge.

I don't even suggest in my posts that anyone use a gas-soaked rag, although I

routinely do it when ether is not available. Too much room for error.

As always, use only a tiny amount of ether. A 1-sec. squirt is generally ample.

Not that I have anything against gasoline. I mix 15% RUG in my filtered WMO.

Runs great in the IDI.

NCTractor6.9

Registered User

Hey guys so I will give an update and answer a few questions.

We couldn't ever get it to start last weekend. after trying to purge the air out we had a few good fires but nothing substantial. Tried to rotate the IP and see if we could tell a difference, nothing at all. I rotated it both ways and not only did I not see a difference, I didn't get a hit on a single cylinder. The temps were pretty cold (Cold for here; upper 20s). But I do have a block heater that I left on the night before we tried to start it. Also, the glow plugs are getting hot. We had a battery charger connected when we tried to start it also, with new battery cables I replaced.

Really stumped at the moment. The plan is to conduct a compression test, I'm just having a hard time finding a glow plug adapter for my compression tester. Additionally we are going to attempt to pull start the truck. At this point I'm not sure of the condition of the internals on this motor but my gut is starting to tell me that I may have a problem internally such as the piston rings.

Thanks for all the helpful replies, keep em coming

We couldn't ever get it to start last weekend. after trying to purge the air out we had a few good fires but nothing substantial. Tried to rotate the IP and see if we could tell a difference, nothing at all. I rotated it both ways and not only did I not see a difference, I didn't get a hit on a single cylinder. The temps were pretty cold (Cold for here; upper 20s). But I do have a block heater that I left on the night before we tried to start it. Also, the glow plugs are getting hot. We had a battery charger connected when we tried to start it also, with new battery cables I replaced.

Really stumped at the moment. The plan is to conduct a compression test, I'm just having a hard time finding a glow plug adapter for my compression tester. Additionally we are going to attempt to pull start the truck. At this point I'm not sure of the condition of the internals on this motor but my gut is starting to tell me that I may have a problem internally such as the piston rings.

Thanks for all the helpful replies, keep em coming

AcIdBuRn02ZTS

Full Access Member

Even with low compression, it should fire. My vote is massive air intrusion. I would go over the fuel system with a fine tooth comb. Pull starting would most likely get it to fire even with air leaks as long as its warm.

Is the block heater working as well? Mine wouldn't poo the breaker but it was melted internally and wouldn't do anything.

Is the block heater working as well? Mine wouldn't poo the breaker but it was melted internally and wouldn't do anything.

fsmyth

Full Access Member

I think you might need to stop and take a breather.

What I would do:

Find an electric fuel pump. doesn't matter what, as long as it is 5 P.S.I. or so.

Get a filter head and 10 micron filter. Can be used later to mount on frame.

Feed from a clean container. 2-5 gals. is sufficient. Fresh winter blend fuel.

Plumb these directly into the IP. A hose clamped onto the hard line going to

the injection pump is fine. If you are SURE your stock filter has no leaks,

feed into that. Bleed 2 or 3 lines. or 4.

Set your IP timing back to where it was when you got it.

Assuming good glow plugs OR good block heater, then it should at least TRY

to start. If it does, THEN move the IP timing forward and back. A tiny bit at a time.

If it does not, then I would next pull the timing cover and make sure all the

gears are lined up properly. If they are, then I would replace the IP.

I would only do this on one that I had not seen running before. You never know.

I am assuming that when you replaced the heads, you observed the rockers

moving. Otherwise I would have ****** a cover, to make sure the cam was turning.

It's going to be something simple. I can feel it from here

PM me for number. We'll get you going.

What I would do:

Find an electric fuel pump. doesn't matter what, as long as it is 5 P.S.I. or so.

Get a filter head and 10 micron filter. Can be used later to mount on frame.

Feed from a clean container. 2-5 gals. is sufficient. Fresh winter blend fuel.

Plumb these directly into the IP. A hose clamped onto the hard line going to

the injection pump is fine. If you are SURE your stock filter has no leaks,

feed into that. Bleed 2 or 3 lines. or 4.

Set your IP timing back to where it was when you got it.

Assuming good glow plugs OR good block heater, then it should at least TRY

to start. If it does, THEN move the IP timing forward and back. A tiny bit at a time.

If it does not, then I would next pull the timing cover and make sure all the

gears are lined up properly. If they are, then I would replace the IP.

I would only do this on one that I had not seen running before. You never know.

I am assuming that when you replaced the heads, you observed the rockers

moving. Otherwise I would have ****** a cover, to make sure the cam was turning.

It's going to be something simple. I can feel it from here

PM me for number. We'll get you going.

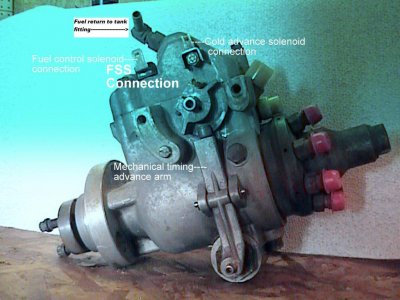

If you didn't mark the lines from IP to each cylinder, some could have been installed wrong. Check from the pic for correct installation.

The cylinders are marked as such.

1 -3 - 5 - 7 are on the passengers side of the engine.

2 - 4 - 6 - 8 are on the drivers side.

The firing order is 1 -2 - 7 - 3 - 4 - 5 - 6 - 8.

1&4-2&5-7&6-3&8 Cyl's @ TDC. 1-4 TDC when timing mark on damper is @ 0. Each 1/4 turn, next 2.

Seems everything has been suggested except doing this.

Take the IP return line hose off cap at #2 injector, unless it's going to #1 injector cap, then that injector cap.

Put the hose in a can or jar to catch the fuel.

With the key turned to run (ON).

Crank the engine for 20 seconds, a pretty good stream of fuel should come out the hose.

If no fuel comes out, disconnect the line from filter to IP, Crank again, there should be a stream, no fuel coming out there, then the lift pump is bad or has been installed incorrectly or you are sucking so much air and hardly any fuel. The lift pump arm has to be installed UNDER the cam shaft lobe.

Please report back with what you find.

The cylinders are marked as such.

1 -3 - 5 - 7 are on the passengers side of the engine.

2 - 4 - 6 - 8 are on the drivers side.

The firing order is 1 -2 - 7 - 3 - 4 - 5 - 6 - 8.

1&4-2&5-7&6-3&8 Cyl's @ TDC. 1-4 TDC when timing mark on damper is @ 0. Each 1/4 turn, next 2.

Seems everything has been suggested except doing this.

Take the IP return line hose off cap at #2 injector, unless it's going to #1 injector cap, then that injector cap.

Put the hose in a can or jar to catch the fuel.

With the key turned to run (ON).

Crank the engine for 20 seconds, a pretty good stream of fuel should come out the hose.

If no fuel comes out, disconnect the line from filter to IP, Crank again, there should be a stream, no fuel coming out there, then the lift pump is bad or has been installed incorrectly or you are sucking so much air and hardly any fuel. The lift pump arm has to be installed UNDER the cam shaft lobe.

Please report back with what you find.

Attachments

Last edited:

NCTractor6.9,

I have a new Facet pump for my truck that I have not installed yet. You could borrow it to make sure you have fuel pressure, using the method suggested by Fsmyth.

Did the PO say why it was parked?

I have a new Facet pump for my truck that I have not installed yet. You could borrow it to make sure you have fuel pressure, using the method suggested by Fsmyth.

Did the PO say why it was parked?

NCTractor6.9

Registered User

Hi all,

I want to extend a thank you to everyone that gave advice and information. We got the beast running this evening after pull starting it numerous times. I'll be lurking around the forum from now on, you guys have been beyond helpful.

Happy oil burning

-T

I want to extend a thank you to everyone that gave advice and information. We got the beast running this evening after pull starting it numerous times. I'll be lurking around the forum from now on, you guys have been beyond helpful.

Happy oil burning

-T

bbjordan

Snow Monkey

Good to see you got it started.

And that is one of the reasons l prefer a manual transmission.

And that is one of the reasons l prefer a manual transmission.

Good to hear!

Similar threads

- Replies

- 30

- Views

- 2K

- Replies

- 2

- Views

- 264

- Replies

- 14

- Views

- 913