Dave 001

Full Access Member

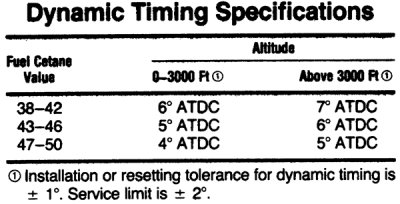

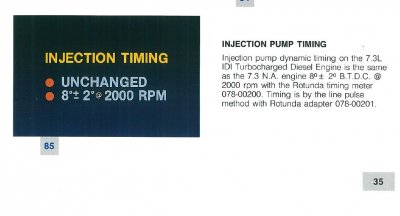

Concerning timing a 7.3........Why are people setting their injection timing at 8.5 deg BTDC when the factory recommended setting is 6.5 deg BTDC? Just bought a Ferrett/Actron set-up and going out to check timing now. Truck starts OK down to about 20 deg F. Below that and starting gets rather hard. There's no place to plug in at work and temperatures are heading back into the single digits.

Thanks.

Dave

Thanks.

Dave