The_Josh_Bear

Full Access Member

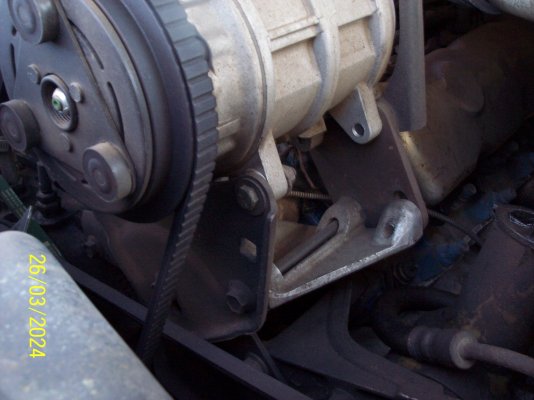

What's "dealer style A/C"? Like they swapped in A/C on a non-A/C factory truck?IDI engines with ‘dealer’ style A/C have them. 84-89. I could be wrong, but I’m pretty sure that’s what they’re for. My 86 has one.

This makes a ton more sense to me, though I'm pretty much a noob at bottom-end rebuilding. I did one 22R years ago. My 4 cylinders of expertise!I read up a little on when to use a reaming tool, and it seems its primarily used BEFORE pulling the pistons to prevent the rings from breaking or causing damage to the ring landings on the piston. Like I said above, they came out pretty easily with just some light tapping, but I did break a number of rings, so in hindsight, maybe that was from removing them.

I was gonna say, just move the drill faster!Yes, I read the reviews. I'll be sure to follow the advice of those that did get it to work. Should be here Thursday along with the hone attachment. My challenge in the past with an electric drill hone tool is that the drill won't go slow enough to make a a proper 45 degree angle. I think my newish brushless electric drill will go pretty slow, so hopefully I won't have to raise and lower the hone like a madman anymore.That's how I broke my previous hone when I accidentally pulled it too far out of the bore. It just broke apart with pieces flying everywhere.

I did my best on the above-mentioned 22r, but it wasn't 45* and that's for sure...I wasn't fast enough.

I did my best on the above-mentioned 22r, but it wasn't 45* and that's for sure...I wasn't fast enough.Great progress and holy cow that's a great big and clean shop! Well done!