david85

Full Access Member

I bought a used ATS 093 turbocharger kit on fleabay a while ago and have been slowly accumulating parts and making repairs to get it ready. Then the home made oil feed line for my current 088 setup cracked for a second time last weekend and put my truck out of commission. I could have simply put a new oil line on, but since I was never too happy with the 088 performance, and there were other problems with it from previous mods, I decided it was time to replace the whole system.

Shoutout to @typ4 for supplying the fuel return kit and turbocharger seal kit. I also had to order several other parts from various places for the new oil line and exhaust components. I debated putting the water cooled center section from my 088 setup into the 093 but decided against it until I do some more homework on how it should normally be set up. Previously, I just had it plumbed in series with the heater core and it wasn't the most robust setup. Since I'm taking longer offroad trips lately, reliability is my biggest concern. Limping home with a massive oil or coolant leak is not fun. I don't recommend it.

The used 093 Fleabay kit came with almost everything, including the downpipe and crossover pipe. They are pretty much toast however, since both are badly rusted and have already been patched by someone a very long time ago. Yes, they are repairable, but since I have stainless steel pipes that I made for my 088, it made more sense to use those. The old pipes are however a useful template to modify my existing stainless steel pipes.

The first major modification was for the downpipe. Although similar, they are NOT interchangeable between the 093 and 088. The 093 is a good 4 inches longer, and that extra length is bent slightly to the side. It's very subtle but the bend is required for the best possible clearance at the firewall/floor seam. I bought a short length of mandrel bent stainless pipe from Amazon to make up this difference. Although the bend is so slight, that anyone could simply notch and weld to get the same result (you won't notice a performance drop from such a mild corner). I also had to adjust the bend at the firewall corner slightly, but I don't know if a factory 088 downpipe would have had the same problem. The one I made often hit the firewall when reversing up a steep hill, so it may have been a build flaw from my end.

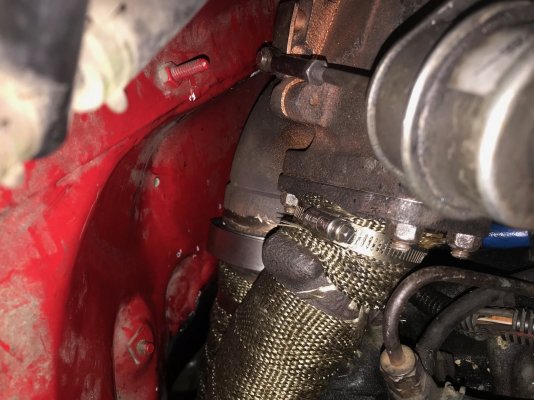

The other modification to the pipe was to add a V-Band Clamp to connect at the turbocharger. This is not strictly necessary since the slip coupling still works fine, but I just the idea of something that seals better than the slip coupling, while also being easier to remove. To weld the cast iron turbocharger outlet, I used 316L stainless rod in two passes. Then I heated up the welded area and let in cool for an hour inside some fire blanket. No cracks are visible so hopefully that's good to go. This is the same method I used for the Y-pipe slip coupling repair.

And then since all the header wrap got soaked in oil, it all had to be replaced with fresh wrap. Hoping to finish the install this weekend so stay tuned for more updates.

Shoutout to @typ4 for supplying the fuel return kit and turbocharger seal kit. I also had to order several other parts from various places for the new oil line and exhaust components. I debated putting the water cooled center section from my 088 setup into the 093 but decided against it until I do some more homework on how it should normally be set up. Previously, I just had it plumbed in series with the heater core and it wasn't the most robust setup. Since I'm taking longer offroad trips lately, reliability is my biggest concern. Limping home with a massive oil or coolant leak is not fun. I don't recommend it.

The used 093 Fleabay kit came with almost everything, including the downpipe and crossover pipe. They are pretty much toast however, since both are badly rusted and have already been patched by someone a very long time ago. Yes, they are repairable, but since I have stainless steel pipes that I made for my 088, it made more sense to use those. The old pipes are however a useful template to modify my existing stainless steel pipes.

The first major modification was for the downpipe. Although similar, they are NOT interchangeable between the 093 and 088. The 093 is a good 4 inches longer, and that extra length is bent slightly to the side. It's very subtle but the bend is required for the best possible clearance at the firewall/floor seam. I bought a short length of mandrel bent stainless pipe from Amazon to make up this difference. Although the bend is so slight, that anyone could simply notch and weld to get the same result (you won't notice a performance drop from such a mild corner). I also had to adjust the bend at the firewall corner slightly, but I don't know if a factory 088 downpipe would have had the same problem. The one I made often hit the firewall when reversing up a steep hill, so it may have been a build flaw from my end.

The other modification to the pipe was to add a V-Band Clamp to connect at the turbocharger. This is not strictly necessary since the slip coupling still works fine, but I just the idea of something that seals better than the slip coupling, while also being easier to remove. To weld the cast iron turbocharger outlet, I used 316L stainless rod in two passes. Then I heated up the welded area and let in cool for an hour inside some fire blanket. No cracks are visible so hopefully that's good to go. This is the same method I used for the Y-pipe slip coupling repair.

And then since all the header wrap got soaked in oil, it all had to be replaced with fresh wrap. Hoping to finish the install this weekend so stay tuned for more updates.

. I've been toying with the idea of putting a v band on both trucks at the outlet now that I see you've done that it's going to happen plus I have a 1 inch body lift so I have more room.

. I've been toying with the idea of putting a v band on both trucks at the outlet now that I see you've done that it's going to happen plus I have a 1 inch body lift so I have more room.