You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wally my new truck TLC

- Thread starter Stu Bailey

- Start date

Stu Bailey

Full Access Member

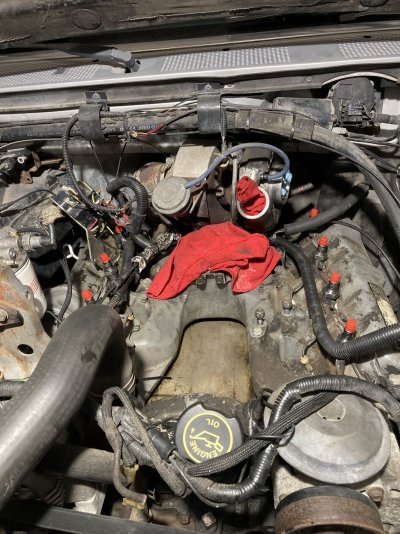

So I got my new injection pump and injectors in! Shout out to Classic Diesel Designs for some quality work

Got the injector bores cleaned out, new injectors in, fuel lines blown out with compressed air, and some other cleaning of parts. Still looks odd have fancy new shiny injectors on a dirty ol' engine. I should have spent my downtime waiting for the parts cleaning more but it was well spent with family, getting house chores done, and other important tasks. But anyway, I should probably install a new o-ring on this fitting that goes into the IP at the center of where all the hard lines come in. I'm thinking one of my extra viton rings for the top of the injectors (return line cap stuff) isn't going to cut it. Anyone have a part number by any chance or specs on one? I guess I could always take it into NAPA and match it up but hey, I've got a few minutes so why not post on the ol' forum!

Pic shows the viton ring from my surplus on there from. Obviously thicker than the original but fits snug.

Got the injector bores cleaned out, new injectors in, fuel lines blown out with compressed air, and some other cleaning of parts. Still looks odd have fancy new shiny injectors on a dirty ol' engine. I should have spent my downtime waiting for the parts cleaning more but it was well spent with family, getting house chores done, and other important tasks. But anyway, I should probably install a new o-ring on this fitting that goes into the IP at the center of where all the hard lines come in. I'm thinking one of my extra viton rings for the top of the injectors (return line cap stuff) isn't going to cut it. Anyone have a part number by any chance or specs on one? I guess I could always take it into NAPA and match it up but hey, I've got a few minutes so why not post on the ol' forum!

Pic shows the viton ring from my surplus on there from. Obviously thicker than the original but fits snug.

Attachments

The_Josh_Bear

Full Access Member

I don't have the size but the type is for an o-ring boss(ORB). These are standard hydraulic type orings. I got a kit from amazon that has served me well(I do some minor work on our work trucks that have hydraulics, too) a NAPA or similar *may* have them...maybe not. Would be worth a call ahead. I can tell you that in hydraulic applications the "close enough" type of standard oring doesn't work, haha. But that's running 2-3k psi behind it.

Stu Bailey

Full Access Member

Yeah I figured there was some pressure at that point. Thanks for the oring classification @The_Josh_Bear , I’m going to look around town and see what’s available.

Cant Write

Full Access Member

Did “your Wally” sit all winter?

How does it do loaded up with the camper pulling your fishing boat? Or is that for this summer?

Any photos of Wally? How did you name it? I was driving “my Wally” home 6 hrs after buying it and thought about my kids, the brown color, it’s size, and thought “Wally the Walrus” cause it’s slow on land and water!!

Anyway, following along and anxious to see how the new IP/injectors work out. Why replace them (the 160k)?

How does it do loaded up with the camper pulling your fishing boat? Or is that for this summer?

Any photos of Wally? How did you name it? I was driving “my Wally” home 6 hrs after buying it and thought about my kids, the brown color, it’s size, and thought “Wally the Walrus” cause it’s slow on land and water!!

Anyway, following along and anxious to see how the new IP/injectors work out. Why replace them (the 160k)?

Stu Bailey

Full Access Member

@Cant Write

He got the name Wally because when I bought the truck it had a steel shell on the back and when I was going through the truck cleaning it out, the name Wally was written on the inside of one of the shell doors. So I said, sure, why not? You look like a Wally!

Truck drives pretty good with the camper but I have yet to pull the boat in line as well. He definitely sat all winter and I’m currently putting the injection pump in but damn, I swear there’s no way to place the lines and pump in with one shot. I know that’s what everyone says but damn they sure don’t make it easy! I have all the stuff moved out the way too!

Any tips out there for sliding this spider in as one unit??

He got the name Wally because when I bought the truck it had a steel shell on the back and when I was going through the truck cleaning it out, the name Wally was written on the inside of one of the shell doors. So I said, sure, why not? You look like a Wally!

Truck drives pretty good with the camper but I have yet to pull the boat in line as well. He definitely sat all winter and I’m currently putting the injection pump in but damn, I swear there’s no way to place the lines and pump in with one shot. I know that’s what everyone says but damn they sure don’t make it easy! I have all the stuff moved out the way too!

Any tips out there for sliding this spider in as one unit??

Attachments

IDIBRONCO

IDIBRONCO

You'll have to hold it with the rear injector lines at the lowest point and the work the pump into place. You may be able to remove a mounting stud from the IP housing to help it slide into place easier. I haven't tried that so I can't say if it will work or not.Any tips out there for sliding this spider in as one unit??

Stu Bailey

Full Access Member

Yeah I don’t know how others with a turbo got it all in one piece, Haynes manual and some other resources mentioned it. I ended up taking off the number 8 and 6 lines and it slid right in.

Those lines were pushing up against the firewall and there was no way around it to angle the pump gear downward into the cover. Good thing was I had access to those two lines for torquing down easily.

Pump is in now so going to bleed it out this afternoon and hopefully have that truck running!!

Those lines were pushing up against the firewall and there was no way around it to angle the pump gear downward into the cover. Good thing was I had access to those two lines for torquing down easily.

Pump is in now so going to bleed it out this afternoon and hopefully have that truck running!!

Stu Bailey

Full Access Member

Injection pump is in and bled! Started putting all the randoms back in (including the gp relay) I have a manual push buttons that I installed and for the life of me, am drawing a blank here.

There should only be 12v at the harness glow plug connector when the push button is closed, correct? I hear the click and the wait to start light illuminates when I push the button and no other time.

I have 12vots from ground to gp harness connector with key on. If the connector is plugged onto the gp and I have the meter probe on a few copper strands coming out that I placed in, I don’t see 12 until I press the button.

I think I’m just lost these days, so much junk going on in life I haven’t been able to do much of anything so I’m turning blue. If the controller isn’t clicking, and the light isn’t illuminating, I shouldn’t be energizing the plugs right!??

There should only be 12v at the harness glow plug connector when the push button is closed, correct? I hear the click and the wait to start light illuminates when I push the button and no other time.

I have 12vots from ground to gp harness connector with key on. If the connector is plugged onto the gp and I have the meter probe on a few copper strands coming out that I placed in, I don’t see 12 until I press the button.

I think I’m just lost these days, so much junk going on in life I haven’t been able to do much of anything so I’m turning blue. If the controller isn’t clicking, and the light isn’t illuminating, I shouldn’t be energizing the plugs right!??

IDIBRONCO

IDIBRONCO

The easiest way to use a manual control on the 7.3 style controller is to have the manual control activate the ground instead of power. If you used that method, you will still have power at the controller without using the button. If you don't hear the click and your light isn't coming on, you're not activating the controller.

Stu Bailey

Full Access Member

Thanks for the confidence boost @IDIBRONCO after a couple different checks I verified it. I did use the tech articles when I installed the push button so I had no doubts on the proper method, worked great for a year until I started messing around with stuff and forgot my base knowledge.The easiest way to use a manual control on the 7.3 style controller is to have the manual control activate the ground instead of power. If you used that method, you will still have power at the controller without using the button. If you don't hear the click and your light isn't coming on, you're not activating the controller.

Truck fired up though and no leaks, new pump and injectors installed and ready for timing! Went halves with a coworker on a Draf timer for these trucks so it should work well this week when I get into it.

I feel a lot more confident though about an IP install which is going to be nice because my dads truck (formerly my 86) is next on the chopping block!

Stu Bailey

Full Access Member

Kids got sick over the weekend and it looks like o have succumbed to the cold as well… doc said our littles one has Croup. Never heard of that! Apparently it’s just a cold with a lot more congestion and inflammation, yada yada. But, I feel like crap so I’m not going out there to time the truck, hopefully tomorrow.

I did walk out and start it up. Fired up without a problem and fast idle solenoid closed like it should after a few minutes. But I did notice that the OD light on the gear selector is now blinking and even when I depress the button it still blinks, any idea as to what fellow Greta lovers?

I have the E40D and my ip has the electronic connector on the side which I believe was related to the transmission? It’s plugged back in now so not sure where the fault could be. Going to read my Haynes and see what I can figure out.

Cheers!

Just found this, sounds about right. Not sure I’d buy a new one, old one worked great before. I’m going to check voltages and position though then see where I’m at.

www.oilburners.net

www.oilburners.net

I did walk out and start it up. Fired up without a problem and fast idle solenoid closed like it should after a few minutes. But I did notice that the OD light on the gear selector is now blinking and even when I depress the button it still blinks, any idea as to what fellow Greta lovers?

I have the E40D and my ip has the electronic connector on the side which I believe was related to the transmission? It’s plugged back in now so not sure where the fault could be. Going to read my Haynes and see what I can figure out.

Cheers!

Just found this, sounds about right. Not sure I’d buy a new one, old one worked great before. I’m going to check voltages and position though then see where I’m at.

Whats a FIPL?

Moderators note: Please see the end of this thread for updated information. Do NOT rely on the below alone. The following article was put together by Bobby aka turbo69 and covers the checking and reseting of the FIPL. Many thanks to Bobby for contributing and we hope that someone...

Last edited:

Stu Bailey

Full Access Member

Noticed I was missing the FIPL throttle arm adapter for E40Ds. Anyone know if they are mandatory? I’m thinking it could be why my over drive light is constantly blinking and I can’t turn it on.

You must be registered for see images attach

IDIBRONCO

IDIBRONCO

Yes they are mandatory. That's what moves the inside part (for lack of a better term) of your FIPL. It's also most likely why your OD light is flashing as well.

Stu Bailey

Full Access Member

Yup. Went to time the truck this evening and figured I’d actually look at the connector thing. Sure enough, it ain’t connected to anything! Haha yeah that adapter fits into the connector and allows the electronic signal to actually pick up on something I imagine.Yes they are mandatory. That's what moves the inside part (for lack of a better term) of your FIPL. It's also most likely why your OD light is flashing as well.

I hopped onto CDD and purchased the last one in stock. Hoping it gets here soon so I can move forward.

Similar threads

- Replies

- 43

- Views

- 4K

- Replies

- 15

- Views

- 2K

- Replies

- 45

- Views

- 2K