tbrumm

Full Access Member

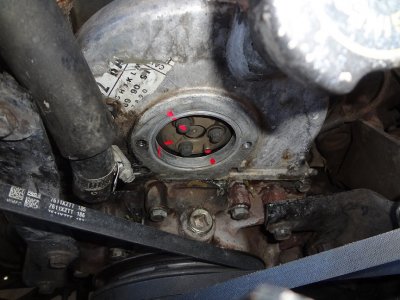

Quite a while back, Mel posted up a pic in thread of a way to "clamp" the IP gear to the cover to keep it form moving and thereby be able to remove the cover with the pump. I thought I had that thread saved in my subscriptions, but I'll be darned if I can find. I ran a search and could not find it either. I know Gary was also posting in that thread. The reason I ask is this: The IP gear cover on my truck has always seeped a little bit of oil down into that "pocket" between the front of the engine and the right side of the water pump. It was a slow seepage and I would just wipe up the little puddle of oil once in a while. Now, it is leaking enough that it is running into the valley pan and then out the drain bolt and onto the starter. I was hoping not to have to mess with this until I buy my Baby Moose next year, but the leak is getting worse. I checked the bolts on the IP gear cover and they are tight. So, if anybody can point me toward this previous thread, or chime in if they have resealed the gear cover, that would be much appreciated. Is there a gasket under the cover, or is it just RTV as I suspect? Thanks! Todd