homelessduck

Full Access Member

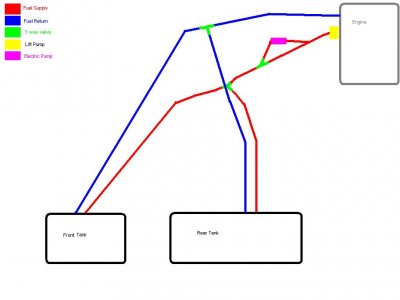

I've been reading thread after thread on the subject but its still hard for me to picture the setup . I ripped a nipple off of my FSV and am trying to decide between the universal FSV and a manual valve conversion . I am also wanting to "Y" in an electric fuel pump that I can switch to for bleeding .. I know its not that difficult , but I can't seem to draw out a solution that works .. probably because of my lack of knowledge as to where the lines run to on the tank . Also , how would you be able to switch between sending units ?

I know this has been discussed multiple times, so sorry for the repeat ..

Does anyone have a diagram the possibly drew up during a similar conversion ??

I know this has been discussed multiple times, so sorry for the repeat ..

Does anyone have a diagram the possibly drew up during a similar conversion ??